Process manufacturing industries produce goods by combining ingredients or raw materials according to formulas, recipes, or chemical reactions, rather than assembling discrete parts. These industries face unique challenges including complex recipes and batch management, stringent execution controls, and product variability. Oracle Manufacturing strengthens Fusion SCM’s capabilities to meet these industry-specific needs in Release 26A, with innovative enhancements, enabling manufacturers to streamline operations, maintain compliance, and maximize efficiency.

Streamlined recipe and batch management

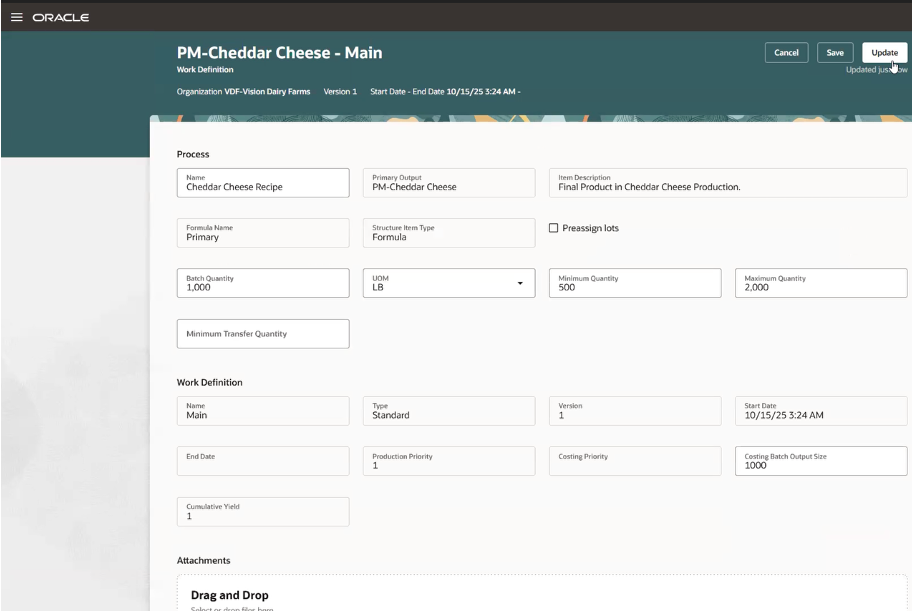

With Oracle’s latest release, recipe management is more dynamic than ever. Formula changes now automatically synchronize with recipes—also known as work definitions—or, in certain scenarios, send notifications for review. Batch quantities are calculated as the sum of contributing ingredients, ensuring accurate tracking of operation yields and providing greater process control and traceability. Work orders can be created using optimal work definitions tailored for specific batch sizes, offering flexibility for different production scales—from small test runs to full-scale manufacturing.

Enhanced process execution and yield tracking

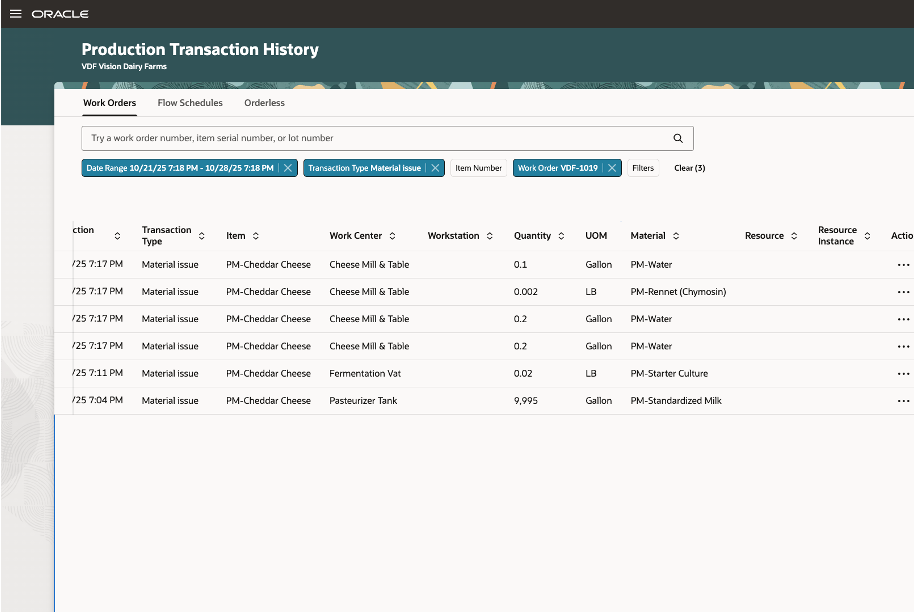

Operators can now report and track intermediate inputs and outputs at each operation, improving visibility into yield variances. This capability enables timely adjustments, supporting process optimization, and consistent product quality. Supervisors can review and address execution exemptions, ensuring traceable records through electronic signature approval—crucial for compliance in regulated industries.

Advanced materials management

Oracle Manufacturing now offers improved lot-level tracking using lot-specific dual units of measure, grade, and shelf life. This ensures that both primary and secondary quantities are captured, and conversion histories are tracked. The enhancements allow selection and tracking of material lots by grade and prevents the use of expired lots, reinforcing compliance and reducing errors for process-driven manufacturers.

New Supply Chain Execution enhancements in 26A

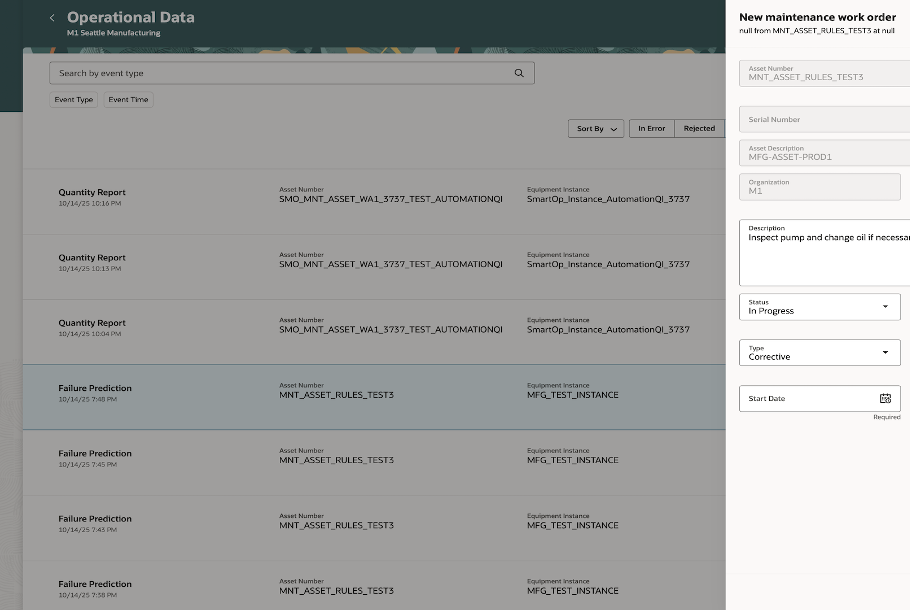

Aside from new manufacturing capabities for process-based industries, we are introducing additional innovations in Oracle Supply Chain Execution, including new AI Agents in Maintenance and Service Logistics, and Smart Operations.

Learn more about these new features and enhancements by visiting the Oracle Maintenance, Inventory Management and Cost Management, Quality Control and Compliance, and Smart Operations feature summaries in the Oracle Supply Chain and Manufacturing readiness pages.