An investigation report on a mid-air crisis involving a well-known airline, concluded the cause of the same, was contamination of the fuel that was used. On further review, it was found the fuel storage tanks were filled with another compound, which had not been thoroughly removed. When the tank was re -filled with the fuel, the fuel became contaminated resulting in engine failure during the flight’s touch down.

Businesses such as aviation and hospitals typically store certain Items in specific locations as they require such considerations as temperature controlled environments, or may be hazardous. These materials are handled in an optimised fashion, where material and Items remain clean and free of contaminants in dedicated areas. A great deal of care is needed to ensure that no other material is stored in those specific storage areas.

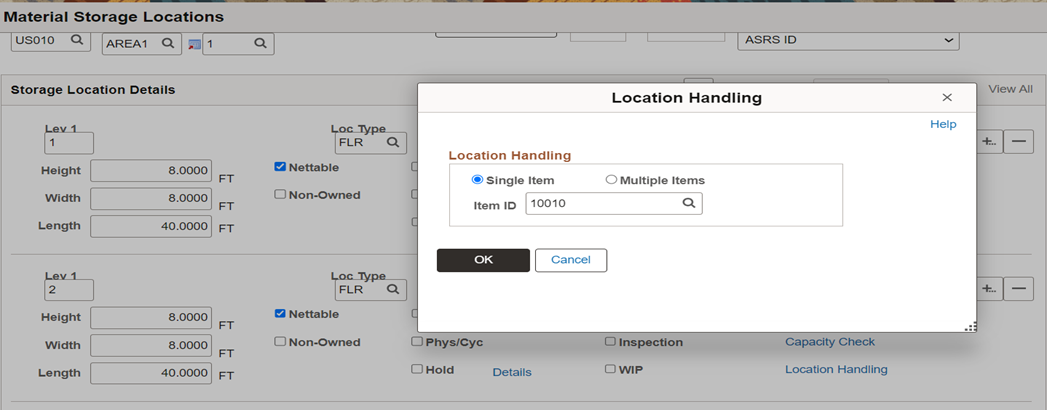

PeopleSoft’s material storage location flexibilities, offers a variety of features in the area of material storage and the “Single Item Location” option is one function to consider. This capability enables materials managers to mark a specific location to hold only a specific material or Item, so no other material is stored in the same location.

This feature can be set up in the Define business Unit Item à Inventory à Shipping / Handling tab , where the Item is marked as “Isolated”. Once this option is selected, Items can be received or transferred only to empty storage locations OR locations that already contain only that specific Item.

As an alternative, the volume / weight capacity check link can also be used to mark this function.

Once the Single Item Option is enabled:

- Only a specified Item is stored in that location.

- There would be no change in the above behaviour, even if the single Item is placed in a container .

- The single Item location can accommodate a new Item, after the location is cleared of the previously available Item.

- In case the location is marked as “Single Item”, without mapping an Item to it, the first Item to be received into that location continues to be assigned to that location.

Mapping Items to a Single Item Location could enable optimized material handling and ensure the Item is managed the way it is meant to be.

Have a glance here to read about Route code