With Contributing Author Anitha Gogineni.

Are you concerned that when backordering a staged delivery line, that material is left in the staging sub-inventory? This would then require you to manually move quantity after each backorder.

This now can’t happen due to the new “Automated Backorder Move” functionality introduced in 12.2.9 that helps to carry out a well laid process for backorder material. You can leave it to the system to generate a Move Order while doing Backorder from Staging.

To set-up this feature, configure Shipping Parameter ‘Automate Backorder Move’ to ‘Auto Transact’ or ‘Auto Allocate’. Then when backordering staged quantity, concurrent request ‘Process Move Orders for Backordered Materials’ is triggered. It creates move order for material movement and triggers concurrent request ‘Move order pick slip’. The ‘Move order pick slip’ request allocates and transacts move order based on shipping parameter ‘Automate Backorder Move’.

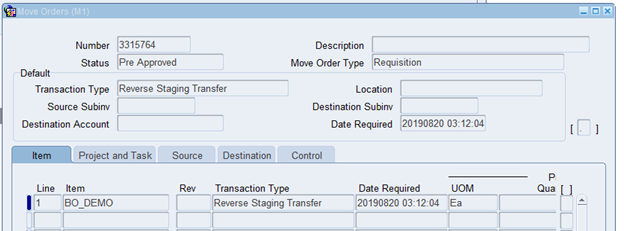

A new Transaction type ‘Reverse Staging Transfer’ identifies the move orders and material transactions for the backordered delivery lines. To move the quantity to a location other than its originally picked location, a programmable custom hook is available.

For details on how to setup, process flow and other helpful information, please check out the below notes.

Vision Demo -How To Move Backordered Material Automatically to Source Location (Doc ID 2580082.1)