Advanced modeling of a full 360º grate discharge flow in a SAG mill

The author is grateful to Nirmal Weerasekara of the Weir Group for his assistance during the preparation of this document.

Through a recent collaboration between Ansys Rocky DEM team and Oracle Cloud Infrastructure (OCI), an advanced semiautogenous grinding (SAG) mill design was analyzed and simulated on OCI’s bare metal GPU shape, using the latest Rocky 22R2 release. This blog post highlights the recent advances in computational simulation capabilities combined with GPU infrastructure in the cloud that enabled the modeling of a real-scale complex industrial equipment with advanced key features, higher resolution, and much improved computational efficiency.

The grate discharge flow in a SAG mill

SAG mills are widely used by the mining industry for primary stage grinding of ore in comminution processes. According to the article, “Is progress in energy-efficient comminution doomed?” milling and grinding are energy intensive processes that can use up to 1.8% of annual globally produced electricity. To improve energy efficiency and increase production, equipment manufacturers and operators continuously look for computational modeling and simulations to guide mill designs. Ansys Rocky DEM is a cutting-edge modeling tool for the industry.

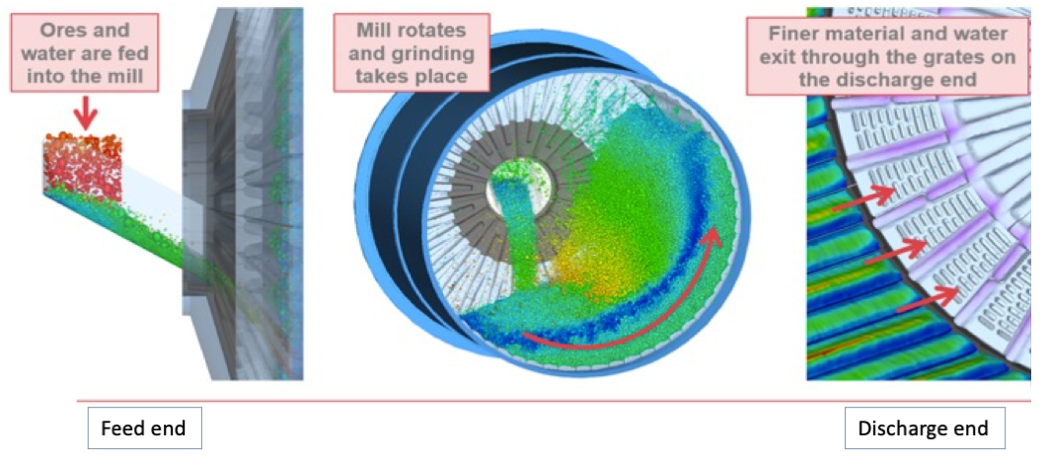

A SAG mill is a large rotating drum in which ore is mixed with steel balls, as shown in Figure 1. As it rotates, the charge (ore and balls) cascades down, and the ore is repeatedly fragmented until its size is small enough to exit the mill through the grates on the discharge end.

|

|

| Figure 1: Basic operating cycle of a SAG mill |

One of the major challenges in SAG mill operation is to control the excessive fine particles and dust generated during griding process. Water is pumped into the mill, but the mix of water and finer particles creates a highly viscous slurry with complex rheological behavior that becomes another major challenge to the mill operation. The slurry must be quickly and effectively removed because it can negatively affect the equipment’s power draw and grinding efficiency.

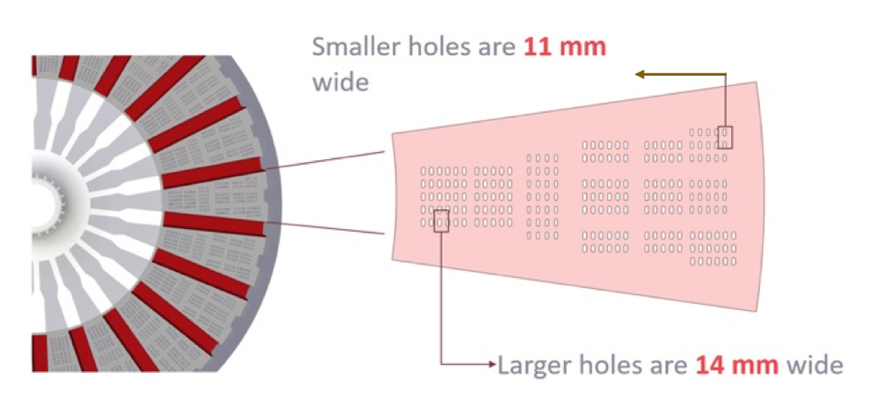

As the grinds and slurry reach the discharge end of the mill, they exit through small holes on the grate, as shown in Figure 2, which are orders of magnitude smaller than the mill and the initial size of the ore. Proper characterization of the flow through the grates is key to improving the equipment design to optimize throughput and avoid issues, such as carryover and flowback.

|

|

| Figure 2. Detailed view of the discharge grate. Adapted from Optimizing pulp lifter design using SPH Simulation: Tritton story and SPH modelling based SAG mill pulp lifter design improvement at Tritton mine and its performance on grinding circuit |

Computational modeling can provide insight to understand the dynamics of the charge inside the mill that has a direct impact on the grinding efficiency, the energy usage, and the equipment wearing. From a modeling and simulation perspective, accounting for such a detailed description of a huge industrial equipment can be computationally complex. In recent years, Rocky has been used to simulate wear modeling and study equipment efficiency using real particle shape representation while considering particle breakage.

In Rocky’s latest release, a mesh-free Lagrange approach for fluids was implemented following the smoothed particle hydrodynamics (SPH) method. The computationally efficient GPU and multiGPU solver enables modeling practical engineering solutions to particle laden free surface flows, such as milling and grinding. Simulating a section of SAG mill offers a good opportunity to put Rocky SPH-DEM to the test. The problem includes a large equipment with complex details, with many particles and a fluid phase with free-surface to be solved in a fully coupled fashion.

OCI: The fastest cloud computing for engineering simulation

Solving problems with this complexity in reasonable turnaround time requires efficient and scalable computing infrastructure. Ansys Rocky team and OCI have collaborated for many years to support our common customers, and we have also worked together to conquer the most challenging engineering simulation problems on the cloud. Last year, we performed a 200-million particle simulation, which was the largest particle model ever reported using a CFD-DEM analysis. This year, we teamed together to solve an advanced DEM-SPH fully coupled model with realistic particle, equipment geometry, and operating conditions.

The backbone of cloud computing resource for this simulation was OCI’s bare metal BM.GPU4.8 shape, The system has eight NVIDIA A100 Tensor Core GPU cards and 40 GB of GPU memory in each card, adding up to 320 GB in total GPU memory—a perfect to fit in the entire 97 million modeling elements. The machine also carries a 27-TB NVMe drive, which is the key to efficiently handling huge volumes of input, output, and scratch data.

The GPU-optimized Rocky DEM-SPH solver was installed on top of Oracle Linux, an Oracle-optimized general-purpose OS distribution. Also preinstalled on the system were NVIDIA GPU drivers, CUDA libraries, and other required dependencies to handle NVIDIA’s A100 GPUs and run Rocky seamlessly. It provides a true turn-key solution for customers to quickly deploy their real industrial engineering production workload.

OCI maintains a dedicated high-performance computing (HPC) engineering team on its staff who works side-by-side with its business partners and customers to provide technical consulting and support services. Most members of the team have extensive industrial experience in their technical field. They’re readily available to roll up their sleeves with the customers to troubleshoot cloud infrastructure issues and provide solution optimization suggestions.

With efficient technical support, full root privileges, and an incredibly fast time-to-market on top of that, you have a tailored solution to tackle real industrial engineering applications. From power on to up and running within a few hours, OCI’s solutions are the number one choice for ROCKY customers.

Computational model and simulation

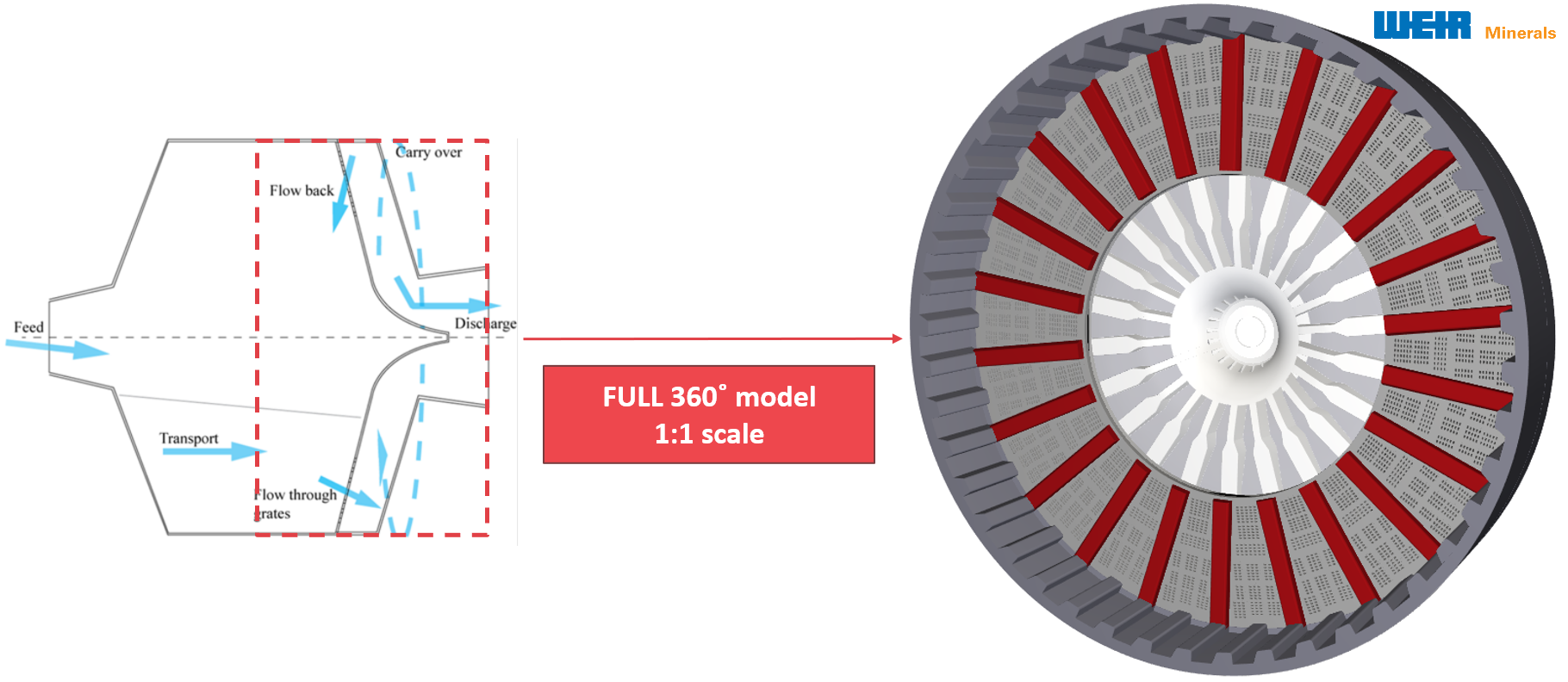

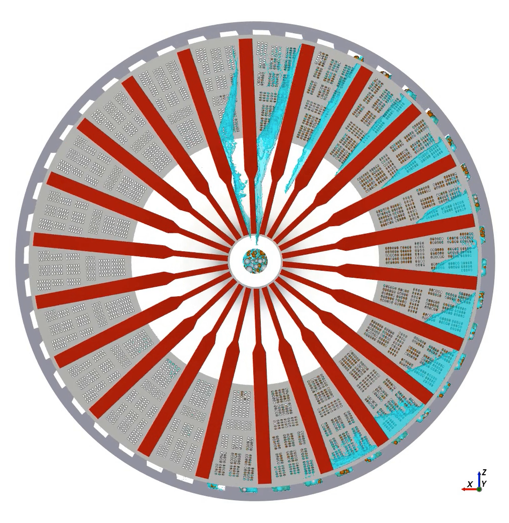

This work focused on a full 360º discharge end of a real-scale SAG mill, as shown in Figure 3. The cylindrical part of the mill is 6.7 m in diameter and 1 m in length and operates at 12.42 RPM (75% of the critical velocity) with 25% filling ratio. 3,500 liters of water are included.

|

|

| Figure 3. Problem geometry. Full 360º representation of the discharge end of a real-scale SAG mill. Adapted from Optimizing pulp lifter design using SPH Simulation: Tritton story and SPH modelling based SAG mill pulp lifter design improvement at Tritton mine and its performance on grinding circuit. |

The steel balls are modeled as spheres, while a comparison is made between spheres and polyhedrons for the ore particles. The following table summarizes particles and SPH elements size and count.

| Setup property |

Value |

| Ore shape |

Sphere |

| Polyhedron (10 vertices) |

|

| Ore size |

[10, 250] mm |

| Steel ball shape |

Sphere |

| Steel ball size |

[31, 125] mm |

| Charge total mass |

31.3 ton |

| Water total mass |

3.5 ton |

| SPH element size |

4.5 mm |

| Total number of Particles |

201,000 |

| Total number of SPH elements |

97,000,000 |

Results

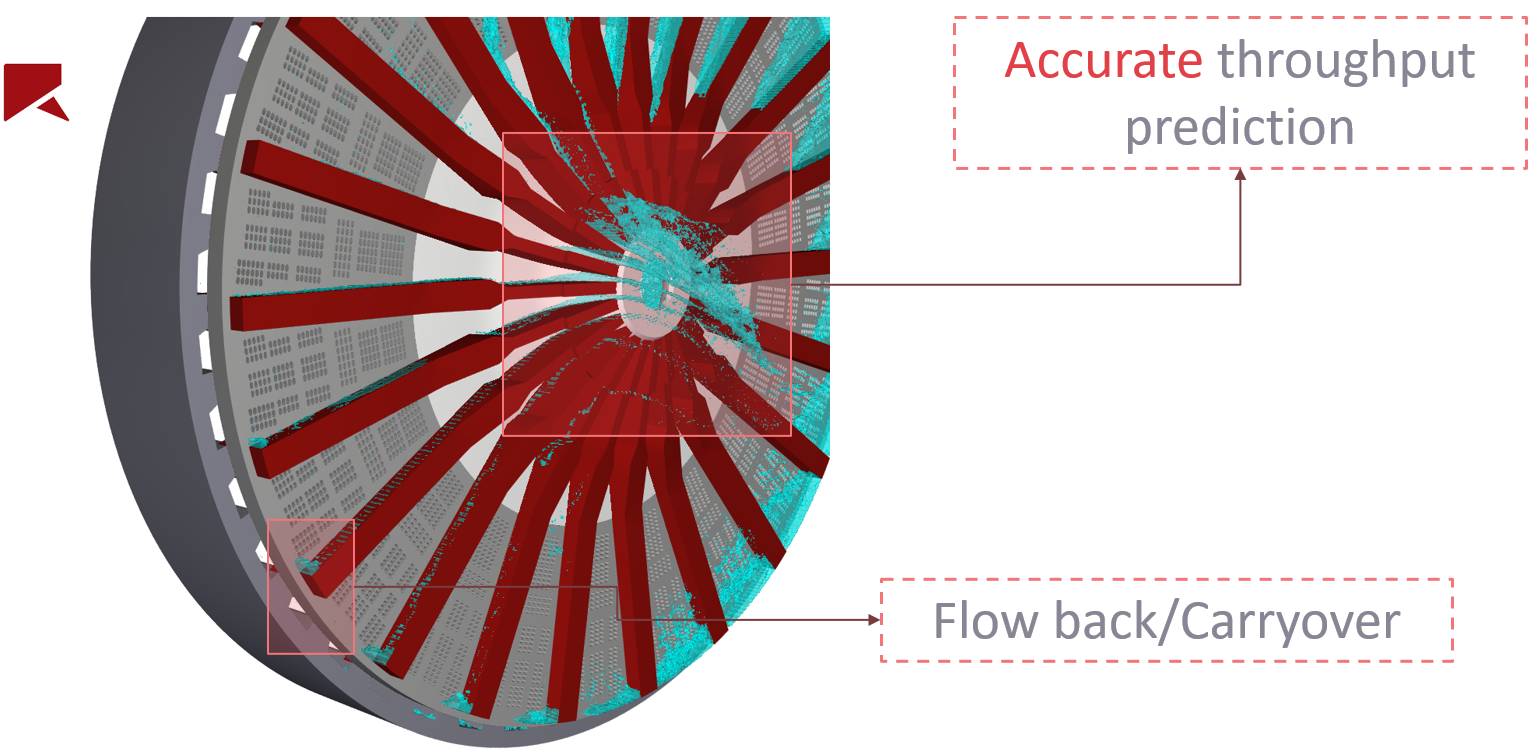

The fully coupled DEM-SPH flow was computed for several mill revolutions, and the results are demonstrated in the animation on the front page of this blog. The complex interplay among the payload of ore, steel balls, and water, and the interaction between the payload and the mill cage and grate were fully captured in the animation. Specifically, the simulation and animation captured furry flow through the grates, and we could clearly see the undesirable phenomena, such as carryover and flowback.

The ROCK DEM-SPH computational model provides rich technical insights and quantitative information to SAG mill designers and operators, enabling them to conduct comprehensive design optimization to improve equipment efficiency.

|

|

| Figure 4: Flow through the grate with carryover and flowback being properly capture. |

What about simulation performance?

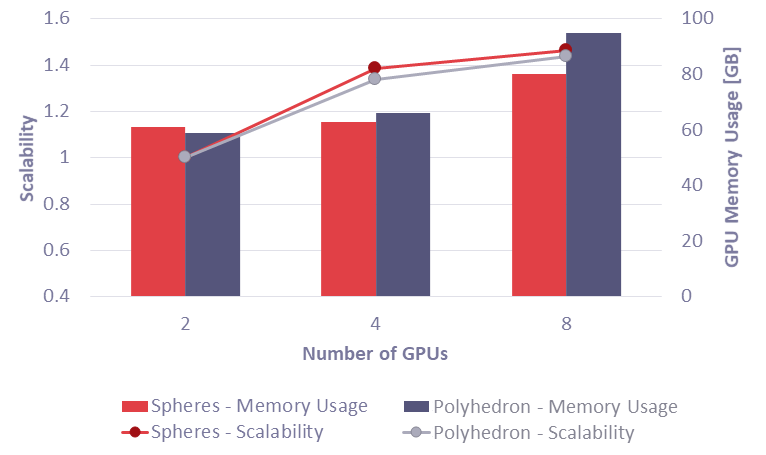

Using OCI’s bare metal GPU4.8 machine, we were able to evaluate the simulation performance and scalability using 2, 4, and 8 GPUs. In Figure 5, the solid lines represent the solver scalability, as given by the ratio between the time for 2 GPUs and those for 4 and 8 GPUs, respectively. The vertical bars represent the total GPU memory usage.

|

|

| Figure 5: MultiGPU performance and scalability |

In general, the simulation got approximately 40% faster when going from 2 to 4 GPUs with similar memory usage, of about 60 GB. For memory, because 4 GPUs cards have 160 GBM of memory, we have room for doubling the problem size. By doubling the number of GPU cards again, we were able to get another 10% improvement in simulation time. On the other hand, the memory usage increased to 75 GB for sphere models and to 90 GB for polyhedron models because of the overhead of exchanging information among the 8 GPUs.

Both sphere model and polyhedron model took a similar amount of time to complete. This simulation cost is more related to the 97 million SPH elements than the shape of the particles. You can use the realistic polyhedron model in your simulations.

| Shape |

Total time |

|

|

|

Spheres |

150 |

|

|

Polyhedron |

152 |

In short, ROCK DEM-SPH computational model provides rich technical insights and quantitative information to SAG mill designers and operators, enabling them to conduct comprehensive design optimization to improve equipment efficiency.

Try out Ansys Rocky on OCI

If you want to learn more about Ansys Rocky 22R2 and its key features and benefits, review the Release Highlights. To learn more about Oracle Cloud Infrastructure, its bare metal and virtual machine shapes for engineering simulation, and the articles referenced in this post, see the following resources:

- OCI Compute Shapes (Documentation)

- High-performance computing

- GPU instances

- Is progress in energy-efficient comminution doomed? (Minerals Engineering Volume 73, 15 March 2015, Pages 1-6)

- Modelling the influence on power draw of the slurry phase in Autogenous (AG), Semi-autogenous (SAG) and ball mills (Minerals Engineering Volume 89, April 2016, Pages 148-156)

- Weerasekara, N.S., Town, S., (2019). Optimizing pulp lifter design using SPH Simulation: Tritton story, In: Proc. SAG 2019, 57, 22–26th September 2019, Vancouver, Canada

- Weerasekara et. al. (2022), SPH modelling based SAG mill pulp lifter design improvement at Tritton mine and its performance on grinding circuit, IMPC Asia-Pacific 2022, Melbourne, Australia