In today’s fast-paced business environment, managing inventory efficiently is crucial. Traditional methods of inventory management, while dependable, often involve manual processes that can be time-consuming and error-prone. Physical inventory count is a critical process in organizations, especially those involved in manufacturing, retail, and logistics. We can understand its significance through several key aspects like accuracy of financial records, operational efficiency, inventory management, regulatory compliance, cost control, and customer satisfaction. Physical inventory counts are vital across various industries to prevent losses and ensure operational efficiency. Major companies like Walmart, Boeing, Johnson & Johnson, Sysco, and Best Buy have experienced losses in the past resulting from physical inventory.

Enter AI-driven automation of physical inventory, a transformative approach that uses artificial intelligence to streamline inventory management, reduce errors, and enhance overall efficiency.

OCI Document Understanding in action

Oracle Cloud Infrastructure (OCI) Document Understanding is an AI service that enables developers to extract text, tables, and other key data from document files through APIs and command-line interface tools. With OCI Document Understanding, you can automate tedious business processing tasks with prebuilt AI models and customize document extraction to fit your industry-specific needs.

OCI Document Understanding is built on Oracle computer vision and natural language processing (NLP) technologies used for core enterprise tasks, such as accounts payable processing, expensing, and content management. OCI Document Understanding gives you all the capabilities to read the manually updated physical inventory tags, which you can update in the system without needing to type in the system.

Customers can also use AI-powered Document Understanding in the following example use cases:

- Invoice Processing: Extract invoice numbers, dates, vendor names, and total amounts from scanned invoices for automated accounts payable workflows.

- Contract Analysis: Automatically extract key clauses, dates, and parties involved in contracts to streamline contract management and compliance checks.

- Shipping and Logistics: Extract shipment details, tracking numbers, and delivery dates from bills of lading and shipping invoices for logistics management.

- Resume Screening: Extract and categorize information such as candidate names, contact details, work experience, and skills from resumes for automated HR processes.

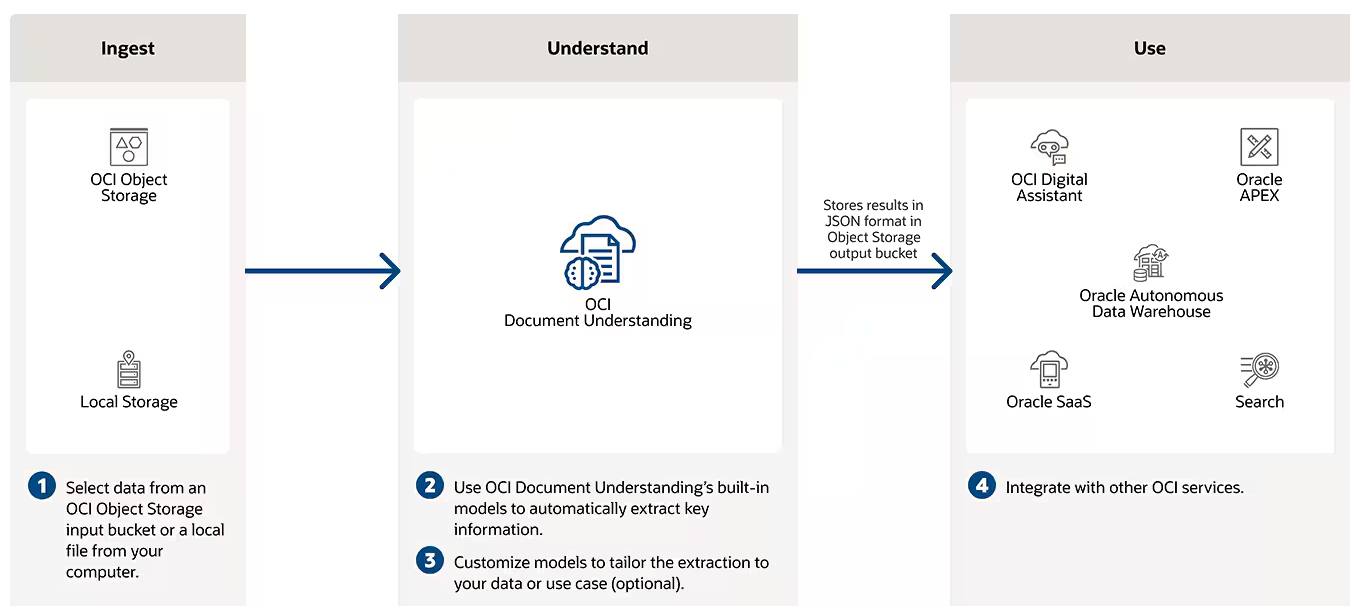

How OCI Document Understanding works.

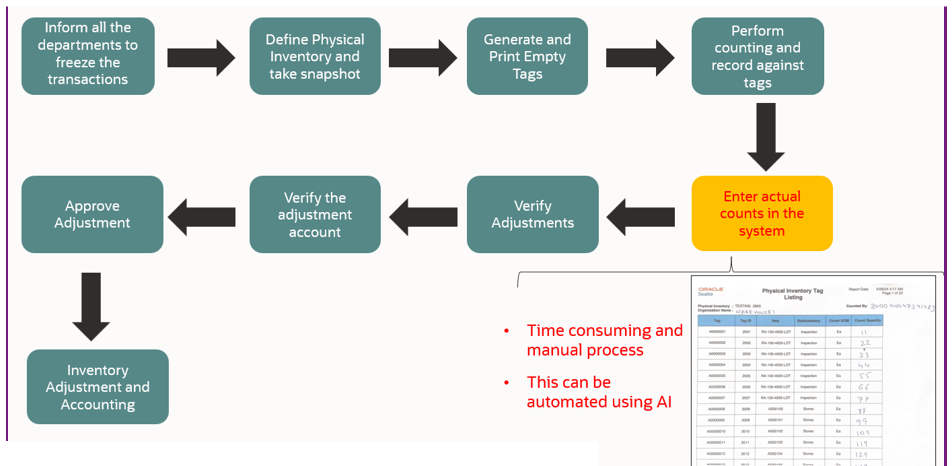

The physical inventory process involves the following steps:

- Inform all departments to freeze all transactions: Before beginning a physical count, the warehouse informs all departments of the physical count duration and that that all material transaction is temporary suspended until completion of physical counts.

- Define physical inventory and take a snapshot: Define the physical in the system, specifying the scope and approval tolerance. Take a snapshot of the system quantity on hand.

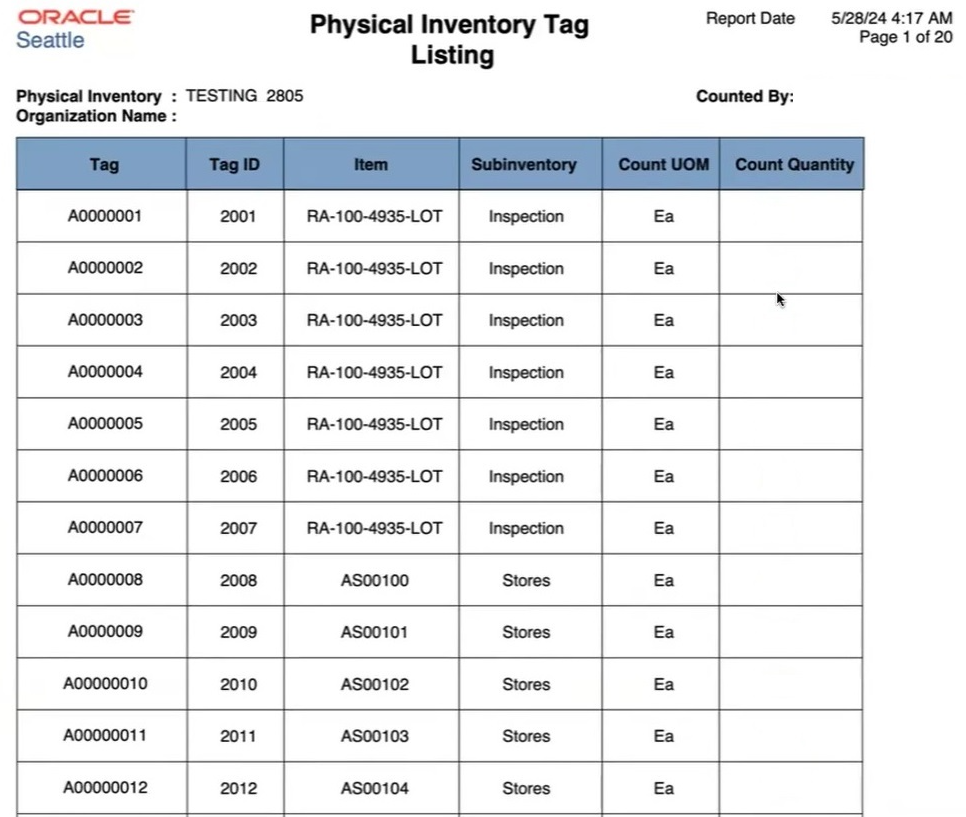

- Generate and print empty tags: Generate the physical inventory tag from the system.

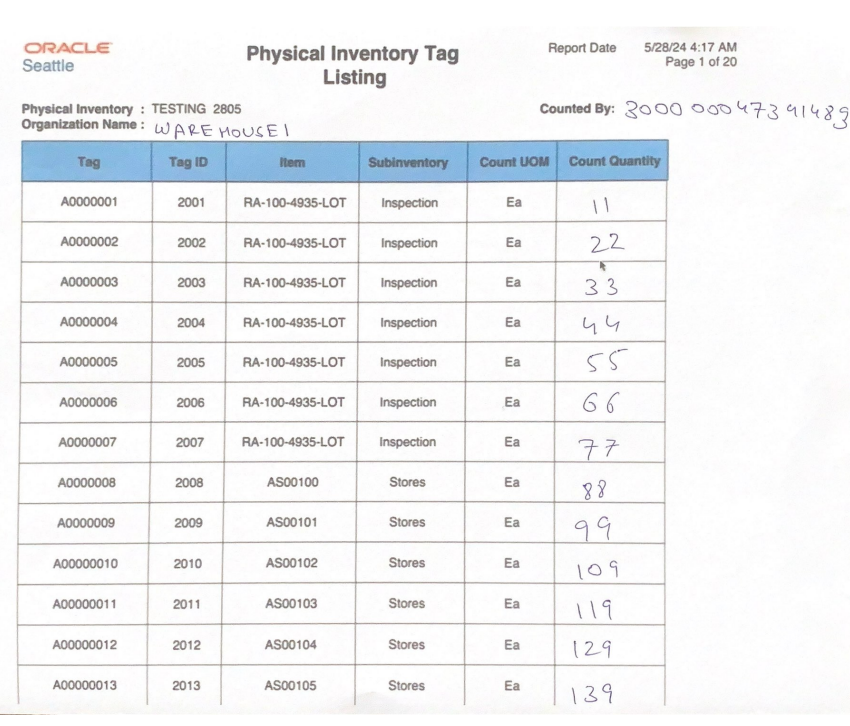

- Perform counting and record against tag: The physical inventory tags are distributed to the counter. The counter counts the items in the specific locator according to the tag and records the actual count in the tag.

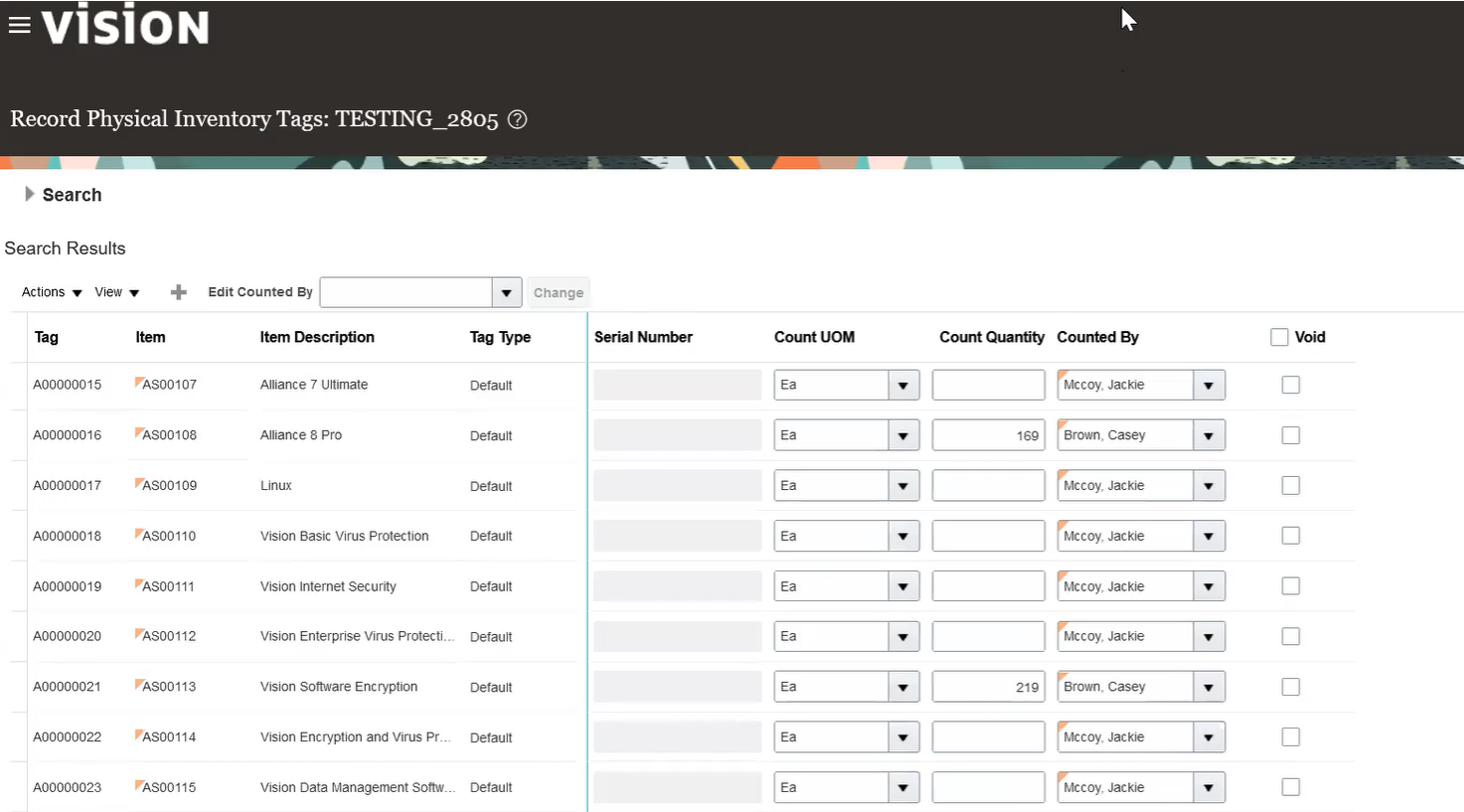

- Enter the actual count: The actual count recorded in the tag is entered into the physical inventory count. The system computes the required adjustment based on the difference between the snapshot quantity and actual count entered.

- Verify adjustment: The warehouse supervisor reviews the count entries that are different from the system quantity on hand and verifies that the adjustments are valid. The warehouse supervisor manually informs Finance of the physical inventory count result and requests confirmation of the adjusted account to be used.

- Verify the adjustment account: The Finance head verifies the adjustment account selected in the physical inventory count and rectifies the account if necessary.

- Approve adjustment: Finance launches the adjustment from the physical count to commit the adjustment for the approved adjustment.

- Inventory adjustment and accounting: The system automatically generates miscellaneous inventory adjustment using the physical inventory count adjustment account.

OCI Document Understanding-empowered physical inventory process

The following process showcases the impact of OCI Document Understanding’s solution and how it helps in accurately capturing information for maintaining efficient and cost-effective inventory in a warehouse or fulfillment center:

- We want to use the AI service offerings from OCI to automate the feeding process back into a software-as-a-service (SaaS) Fusion application.

- The Enterprise Scheduler Service (ESS) job used to print the physical inventory tags is changed to accommodate a new format. The new ESS job has an identical data model to the original ESS job but with a different report template to produce the report output in the new format.

- We create a modified version of the standard ESS job, “Print Physical Inventory Tag Listing Report” to add a custom layout to have the physical inventory report printed and emailed to the shop floor team.

- This report printout is filled in, photographed, and uploaded into the APEX App for further processing.

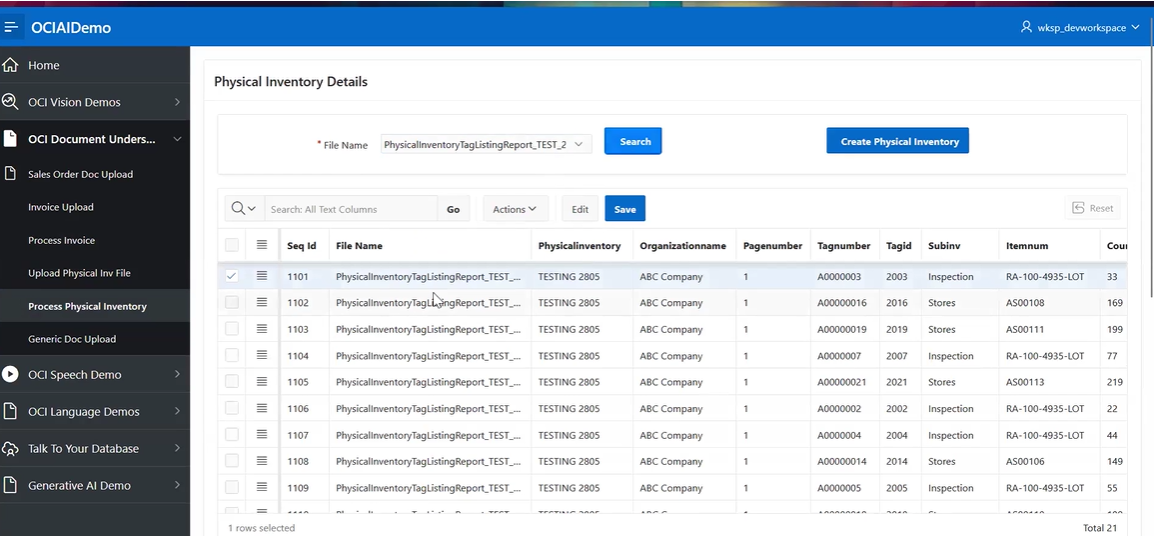

- The report data extracted using the OCI AI Document Understanding service is fed into Apex and is available for users to verify the data, and after inspection, they can further process into SaaS through the APEX application. This step helps in the physical inventory automation without incurring costs for application development and procurement or human personnel to create and maintain this functionality.

- Executives on the shop floor need only a printout, which can include the counts populated of the individual items.

- The executive takes a picture of the printout from their mobile device and uploads it into the APEX portal to begin the process of ingesting the observed inventory counts into the system.

- APEX shows the data extracted from the report for user confirmation. The user will get recheck the counts identified by the Apex app and does any modifications to it if needed. Once the user is fine with the counts, he clicks on the Process Physical count button and the data will be pushed into the inventory module.

Template change of a ESS job: Print physical inventory tag listing report

The seeded layout that OCI Document Understanding reads is complex. The following image show a simpler custom layout:

The system processes the job through the following steps:

- The user uploads the image into the APEX app.

- APEX pushes the image into a predetermined OCI Object Storage bucket.

- An OCI event is raised, and the event is pushed into OCI streaming.

- Oracle Integration Cloud (OIC) subscribes this event and calls OCI Document Understanding to extract the data from the image.

- The data extracted is pushed into Object Storage, where OIC reads it from the output OCI Object Storage bucket. This data is exposed to the user through APEX.

- The user rechecks the counts in APEX and modifies the counts and other fields as needed and then selects Process physical counts to push the data into the inventory module.

The following image show the physical Inventory count captured in Fusion with the user and organization manually written on the tag report:

Document Understanding reads the document using the OCI Document Understanding REST API. After the data is populated in the APEX UI, the user can verify and update the data.

Finally, the physical inventory is updated in Fusion.

Conclusion

Physical inventory is a complex process for organizations because it requires coordination across functions. It’s also costly because the inbound and outbound activities in the warehouse or fulfillment center must be paused for the entire period during which counting happens. The required manual entry into the Fusion application makes it time-consuming and error prone.

Oracle Cloud Infrastructure Document Understanding plays a transformative role and helps to quicken the process and reduce error, reducing costs and simplifying the entire process.

For more information, see the following resources:

- Intelligent Document Processing with Oracle Integration Cloud and OCI AI Vision Service

- Announcing OCI Document Understanding custom model support

- Automate Invoice handling using Oracle APEX and OCI Document Understanding