Today, there is a great focus on ESG initiatives across organizations. Various regulators and standards bodies such as the Sustainability Accounting Standards Board (SASB), Climate Disclosure Standards Board (CDSB), International Integrated Reporting Council (IIRC) and in Europe the Corporate Sustainability Reporting Directive (CSRD) are mandating that organizations take on sustainability initiatives and cut on carbon emissions.

Supply chains generate 60% of global emissions [1]. Supply chains hold 5.5 times more carbon intensity than the rest of the business [1]. This is the impact of sourcing the product, manufacturing the product, its distribution, transportation, and delivery to last mile.

There are 3 scopes of emissions:

Scope 1 – direct emissions from owned or controlled sources.

Scope 2 – indirect emissions from the sources of purchased energy.

Scope 3 – all indirect emissions that occur in the value chain of the reporting company, including both upstream and downstream emissions.

Are you ready to reframe your supply chains for sustainability?

The Supply Chain Operation Managers, Chief Sustainability Officer (CSO), Chief Operating Officer (COO) and other Executives want to know and measure how their organization is progressing against the sustainability target. Solutions to sustainability problems can be addressed by providing visibility on sustainability parameters across the various supply chain functions. A solution can be crafted to measure each of the sustainability parameters and then compared to industry benchmarks to understand how the organisation is progressing against identified parameters.

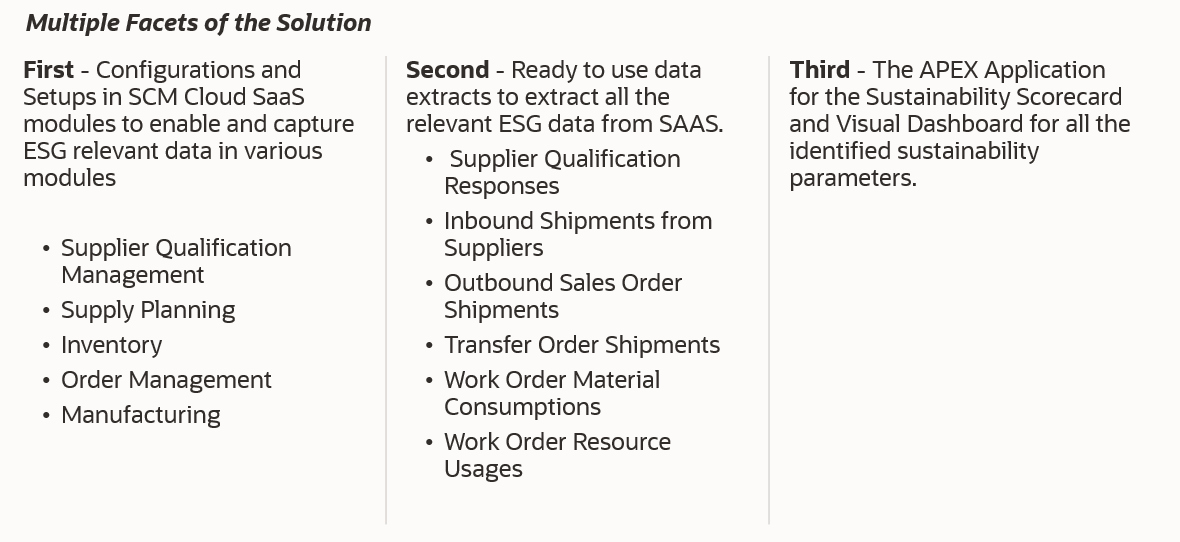

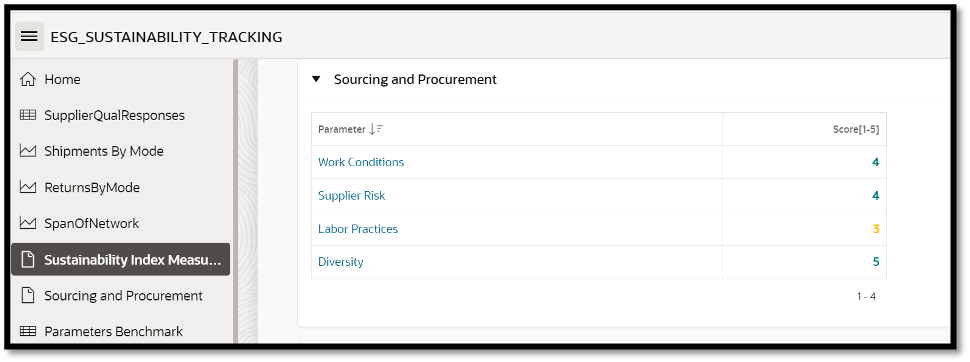

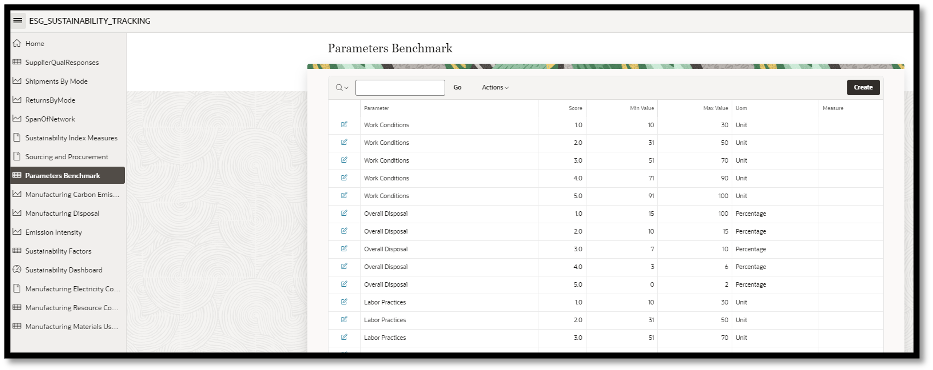

The above solution extracts raw transactional data from SCM Cloud, compares the data with industry standard benchmarks [2] and then provides the score on each of the sustainability parameters on a scale of [1 – 5] which the supply chain managers and executives can monitor and improve. The score of 5 signifies that an organization is meeting or exceeding the industry average and score of 1 signifies that an organization is performing well below the industry average.

Sustainability Index Tracking

A Supply Chain Operation Manager reviews the sustainability index scores for the identified sustainability measures across all supply chain functions. The scores shown below for “Sourcing and Procurement” are within an acceptable range for the company.

The scores in the “Logistics and Transportation” section catches the eye of operation manager. The operation manager notices the scores shown below for the outbound logistics area are very low.

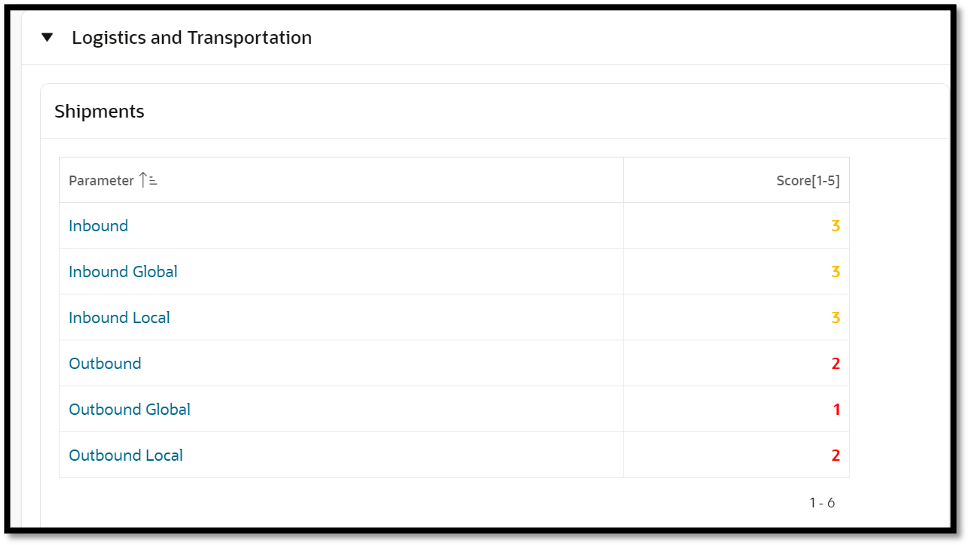

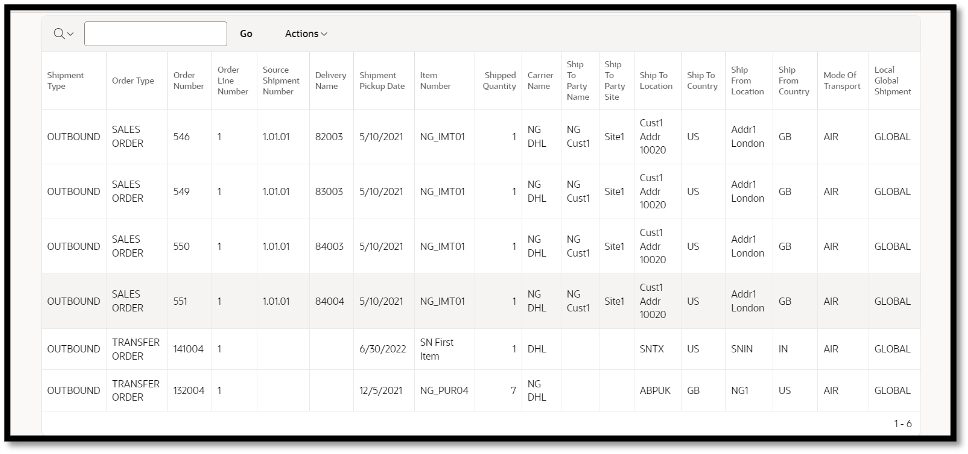

The application provides insight into which area operation manager needs to focus on, and operation manager can immediately act on it. The operation manager digs deep into the Outbound Global parameter as shown below and notices the mode of transport used for global shipments is entirely through Air, which contributes to higher emissions. With this knowledge, operation manager can explore alternate modes of transport, like Ocean, for future shipments.

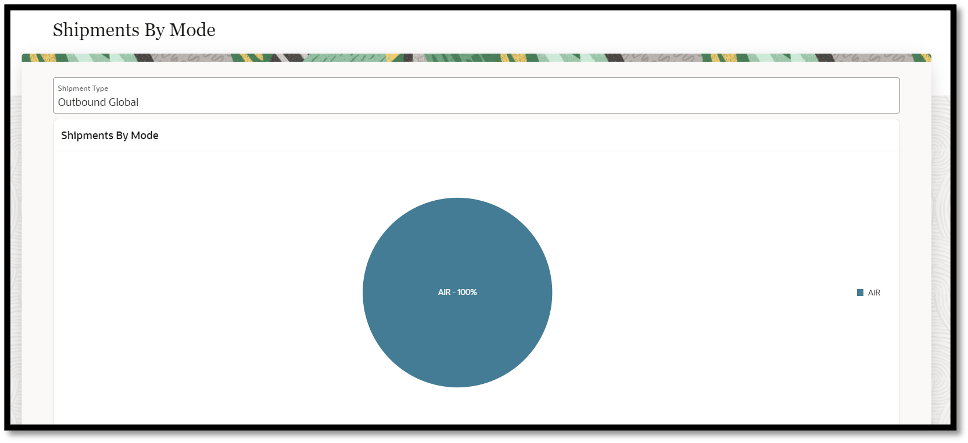

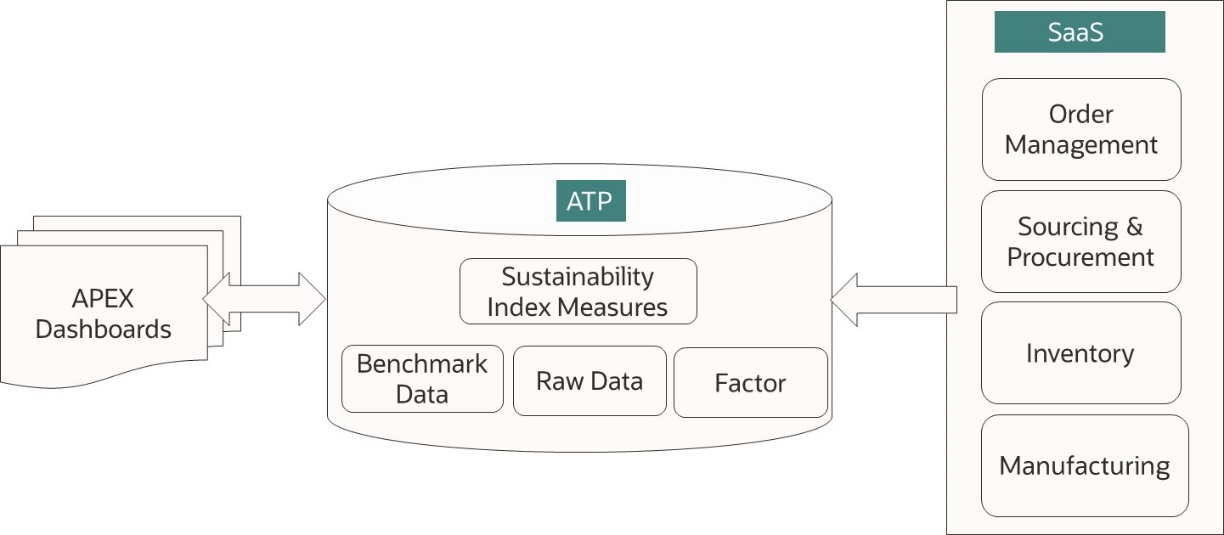

Below is the logical architecture for the solution. The solution captures data from the single suite of Oracle SCM applications covering Sourcing, Manufacturing, Inventory and Order Management and then pushes the data to Oracle ATP database and uses APEX to provide the visual dashboards against each of the identified sustainability measures.

Logical Architecture

How does the solution work?

The Sourcing Administrator sets up pre-defined qualification areas like Diversity, Labor Practices, Work Conditions, and Supply Risks with automated scoring and outcome based on the supplier responses. The sourcing administrator runs the initiatives for the qualification and categorizes the suppliers based on the qualification outcomes across the various qualification areas.

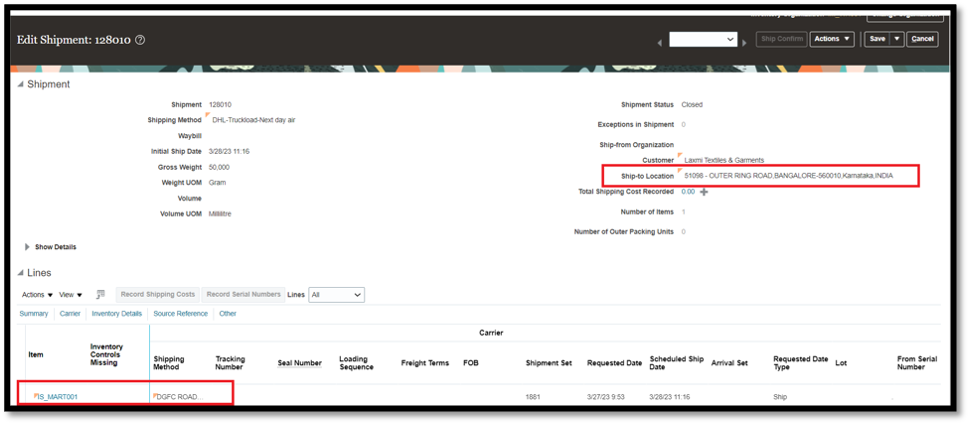

The Supply Chain Warehouse Operator receives the goods from the suppliers through inbound shipments coming through various ship methods as defined in the shipping network. The warehouse operator arranges shipments that need to be delivered to customers including the mode of transport and the desired ship methods.

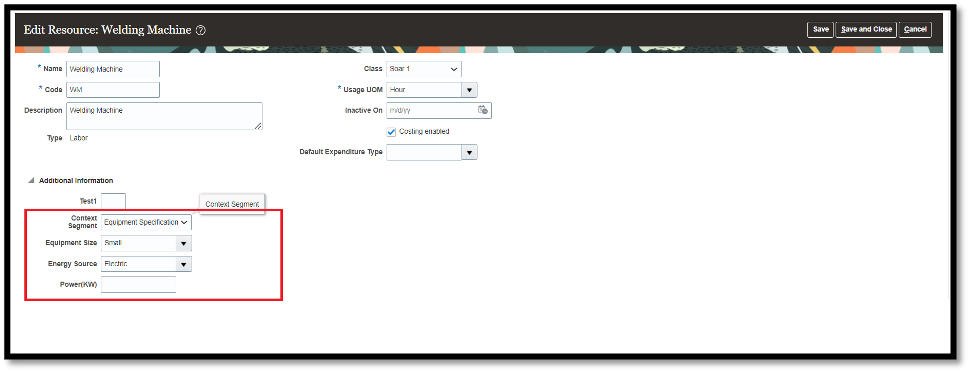

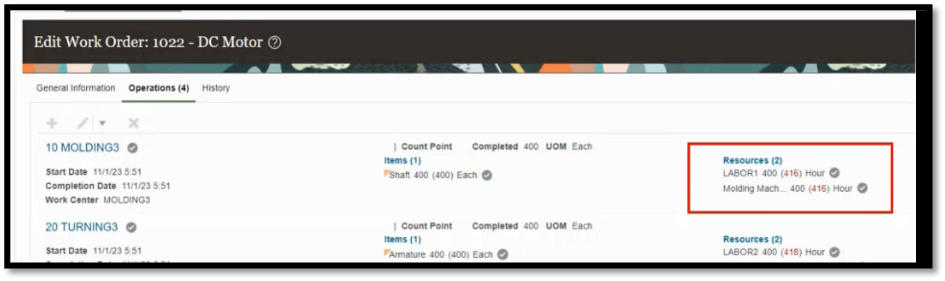

The Production Supervisor defines the work definition with the identified operation to be carried out for production. These operation uses the resources like labor and equipment. The production supervisor captures the specifications like Size, Energy Source and Power of these operational equipment during the work definition setup.

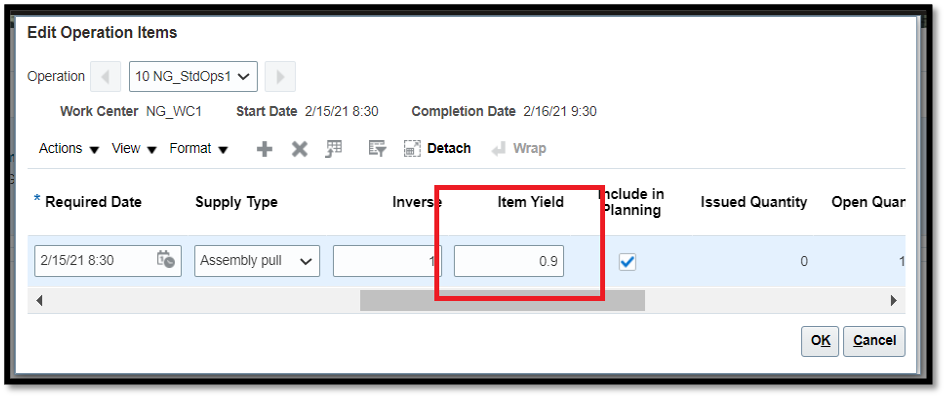

The supervisor also keeps an account of yield for various components used for the finished goods and keeps track of completed work orders for resource usage.

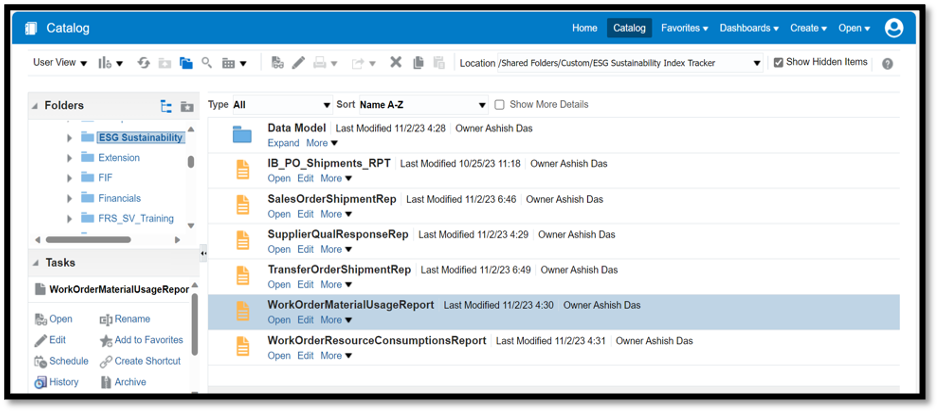

In Sustainability Index Tracking solution, we can leverage best-of capabilities of Oracle SaaS and PaaS offerings. The day-to-day transactional data can be extracted from Oracle Fusion SCM modules like Sourcing and Procurement, Manufacturing, Inventory and Order Management to autonomous transaction processing (ATP) database using the BIP Reports and Oracle Integration Cloud.

Using the power of Oracle APEX and SQL stored procedures in ATP database these transactional data can be compared with industry benchmarks [2] to calculate and derive the sustainability scores on various parameters in scale of [1-5]

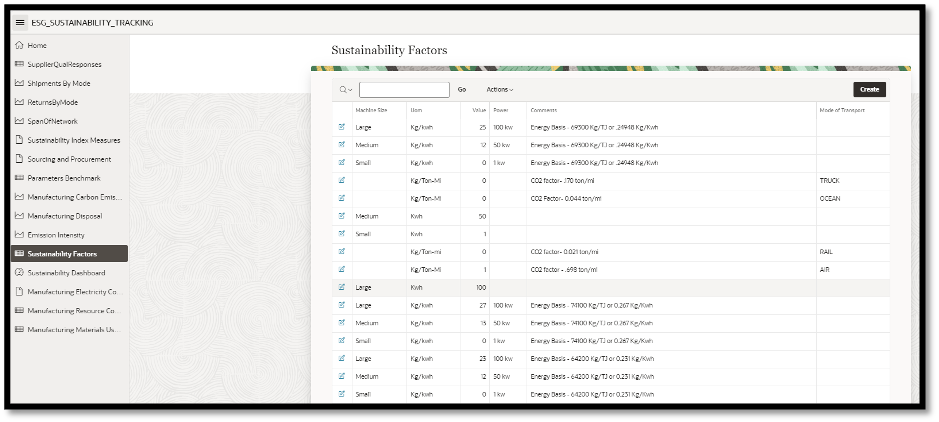

The solution uses the published emission factors on energy basis and Ton-Miles [4] to calculate to emission figures for various operations.

The parameters that can be measured and scored across the supply chain functions is illustrated in the table below.

| Functions |

Parameters |

| Sourcing and Procurement

|

|

| Logistics and Transportation |

|

| Manufacturing |

|

| Supply Chain Network |

|

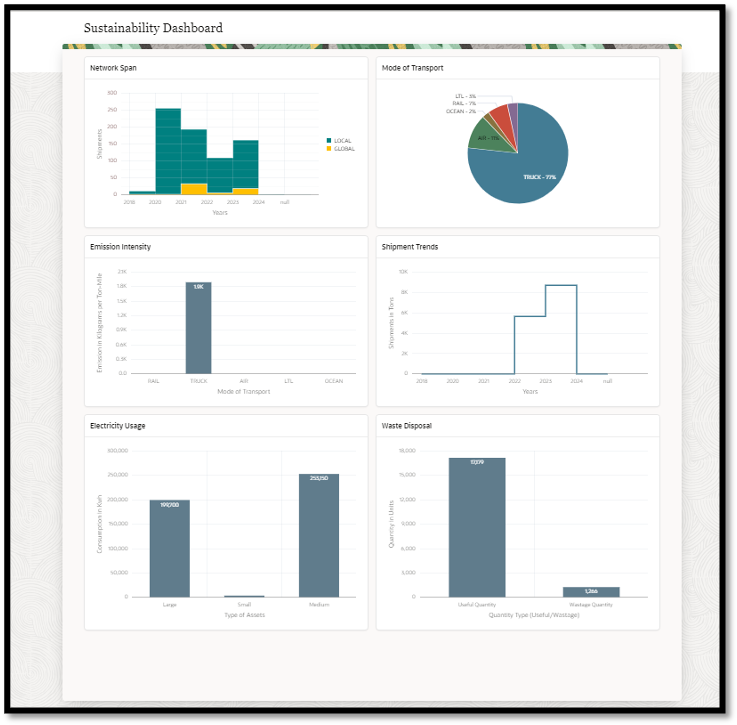

The solution can have a dashboard which provides a visual view on various sustainability measures like network span, mode of transport, emission intensity, shipment trends, electricity usage and waste disposal.

References

- https://www.accenture.com/in-en/insights/supply-chain-operations/supply-chains-key-unlocking-net-zero-emissions

- https://www.apqc.org/resource-library/resource-listing/apqc-talks-sustainability

- https://www.apqc.org/resource-library/resource-listing/procurements-role-sustainability

- https://www.epa.gov/climateleadership/ghg-emission-factors-hub

- https://www.epa.gov/climateleadership/simplified-ghg-emissions-calculator