Sign in with SSORecycling has become a global imperative as a way to replenish precious resources and reduce waste. All of us are aware that we can recycle items like newspapers, glass, plastic bottles and aluminum cans, but what about bigger items like car parts, metals and raw materials? Tons of products are discarded every year and our landfills are now overflowing. Part of protecting the earth’s precious resources for future generations involves looking at innovative ways to recycle items to prevent waste and pollution from manufacturing. Statistics compiled by the University of Central Oklahoma reveal that recycling can dramatically reduce pollution, from landfill dumping to mining waste by up to 70%.

One item that can be effectively recycled is lithium-ion batteries, yet every year it is estimated that 1.8 million used batteries are not responsibly recycled.[1] Although the rate of recycling has risen considerably from the 5% recycling rate calculated by Friends of the Earth in 2010, there is still a very long way to go. The environmental impact of not recycling batteries is huge as very scarce metals like cobalt are wasted, ending up in landfills with toxic materials spreading into water supplies. In some parts of the world, it is illegal to not recycle batteries. In addition to the environmental impact of recycling, recycling reduces the human rights issues associated with the mining of some raw materials like cobalt, much of which is mined in the DR Congo by slave labor including children.

An Industry First: Environmentally Responsible Sourcing with Volvo Cars

Volvo Cars has long been committed to the highest standards of safety, responsible sourcing and sustainability practices. The company has made it a point to act responsibly with regard to the recycling of batteries and other automotive materials. Volvo Cars was the first major premium car brand to commit to a hybrid or full-electric powertrain for all its models, with the aim of driving the automotive sector forward and improve the quality of the air in our cities.

Now, in another world first, Volvo Cars has just implemented the first blockchain traceabilty system for tracking the cobalt it uses in its electric vehicle batteries. They started with scrap lithium-ion batteries from discarded phones and laptops, from which the raw materials were recovered and then tracked right through the supply chain to their battery manufacturer CATL and then to Volvo Cars. Recycled batteries are a major untapped resource and will eventually account for more of the battery materials used in cars, trucks and buses, because the qualities of lithium and cobalt being mined are modest compared to the total expected global demand. The end-to-end process is complex, involving many geographically dispersed companies across the supply chain from raw materials to new electric vehicle batteries.

Volvo Cars is on a mission to create electrical vehicle fleets. Indeed, Volvo Cars has taken a leadership role in environmentally responsible automotive manufacturing with a charter to move their entire portfolio of vehicles into electrification. Today, consumers can buy plug-in hybrid Volvo cars that offer the choice to run on gasoline or battery electric power. By 2021, Volvo Cars plans to offer five new battery powered electric vehicles. [2] These cars will be powered by lithium ion batteries, dependent on cobalt supplies.

Circulor and Oracle: Recycling Cobalt with Blockchain

The demand for cobalt necessitates the recycling of batteries, as there is not enough freshly mined cobalt to meet the current demand. This makes it essential to responsibly use and recycle existing cobalt supplies. Battery suppliers for Volvo Cars electrification initiative are required to provide traceability of the raw materials used in the batteries.

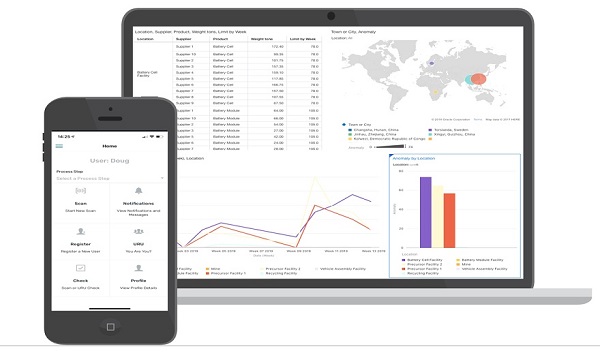

Looking for a solution to help effectively track and trace the materials in the electric car batteries, verify recyclability of materials and ensure regulatory compliance, Volvo Cars turned to Circulor, a UK company that specializes in using blockchain technology to track and trace raw materials in supply chains.

Circulor has developed a platform that uses blockchain technology from Oracle to create an immutable chain of custody record in the supply chain, combined with artificial intelligence algorithms to support due diligence and identify data anomalies to help target compliance and investigative action. This has been field tested and used operationally for Tantalum mined in Rwanda (tantalum is a conflict mineral used in capacitors in our phones and laptops) and now for the Cobalt used in Volvo Cars’ electric vehicle batteries.

The Benefits of Oracle Blockchain for Supply Chain Tracking

Oracle’s pre-assembled blockchain platform enabled Circulor to focus on their specialty—minerals tracking—without spending time and effort on building blockchain infrastructure. Oracle Blockchain offers users an easy way to set-up a secure blockchain right out of the box:

- A fully managed cloud platform for rapid provisioning and simplified administration of blockchain networks

- Includes components: infrastructure dependencies, Hyperledger Fabric components, REST proxy, and operations console

- Easy partner onboarding with pre-integrated, built-in identity verification

The benefits of using Oracle Blockchain to track and trace raw materials and automotive parts are numerous according to Circulor’s CEO Douglas Johnson-Poensgen. “While we created the business logic, user interfaces and algorithms to verify data, we didn’t have to worry about our ability to offer an enterprise-class solution. Oracle’s blockchain solution delivers enterprise performance, security and scalability right out-of-the-box.”

With the supply chain traceable and verified by blockchain, both Volvo Cars and their customers can be assured of the integrity of car parts, responsible sourcing and compliance with regulations.

[1] Source Johnson Controls Power Solutions via MyBatteryRecyling.com

[2] Volvo’s Electric Car Initiative (https://www.volvocars.com/us/about/electrification)