Co-authored by

Douglas de Andrade de Souza, PMO, Inpasa

Inpasa, one of the largest producers of corn ethanol in Latin America, now has full control over its logistics, drastically reducing errors and improving management decision-making with Oracle APEX and Oracle Exadata.

Business Challenges

Inpasa is considered the largest corn ethanol producer in Latin America, with seven operating units—two in Paraguay and five in Brazil. The company produces more than 13 million liters of ethanol per day, more than 20 million tons of grain annually, 8,000 tons of DDGS (Distiller’s Dried Grains with Solubles) per day, and more than 4,000 megawatt-hours (MWh) of energy every day.

The growth generated through acquisitions and the evolution of products and services resulted in an increase in operational complexity, prompting Inpasa to create a strategic plan to align growth demands with market opportunities. Typical tasks performed by Inpasa teams are marked by reliance on manual work with overstrained service channels to handle orders, deliveries, and customer queries, making it difficult to align production to real-time market demand.

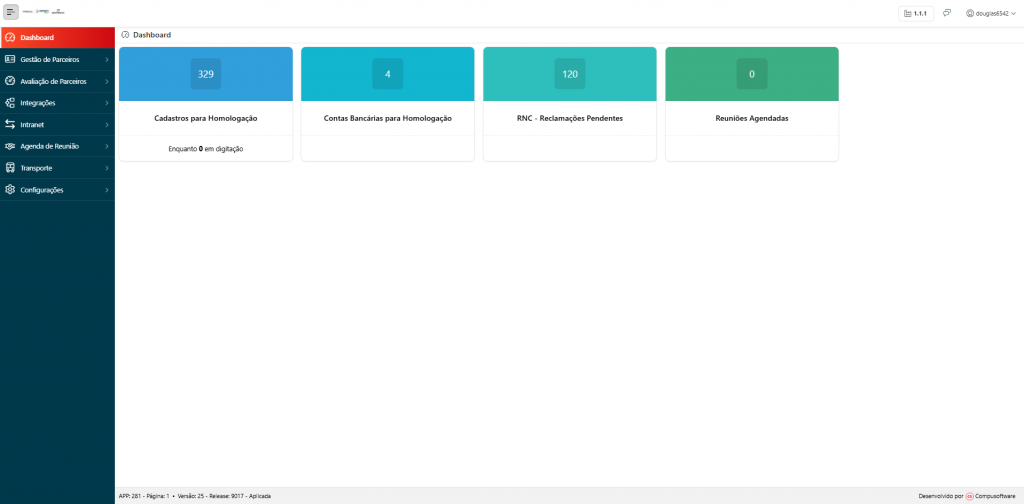

To support business expansion targets while ensuring operational excellence, Inpasa decided to use Oracle APEX and Oracle Exadata to build the Portal de Agendamentos (the “Scheduling Portal”), a system designed to modernize logistics and customer service management, with rapid deployment and built-in scalability.

Why did Inpasa choose Oracle APEX?

Oracle APEX was chosen due to its capability to build a scalable, future-ready platform capable of integrating order management, logistics, and customer service in a single place, reducing manual work and enhancing process transparency.

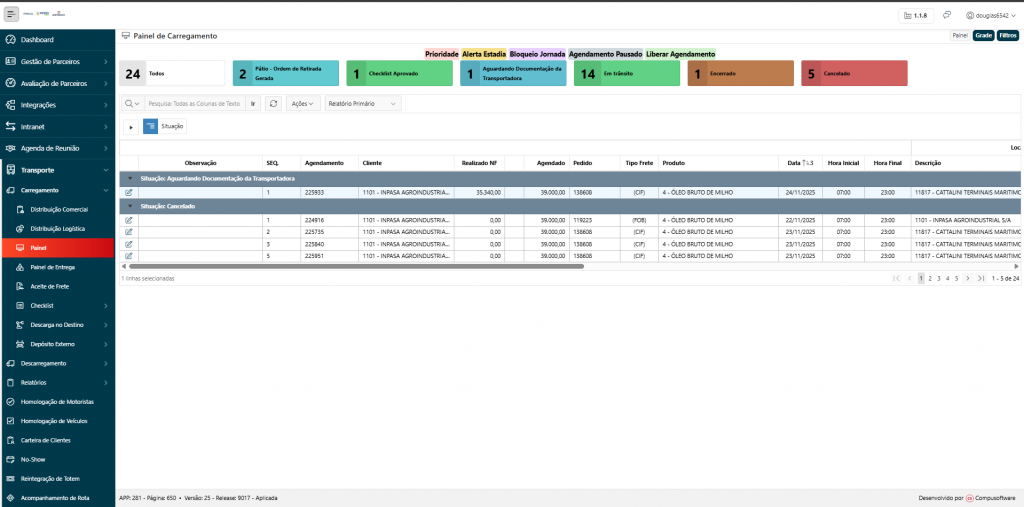

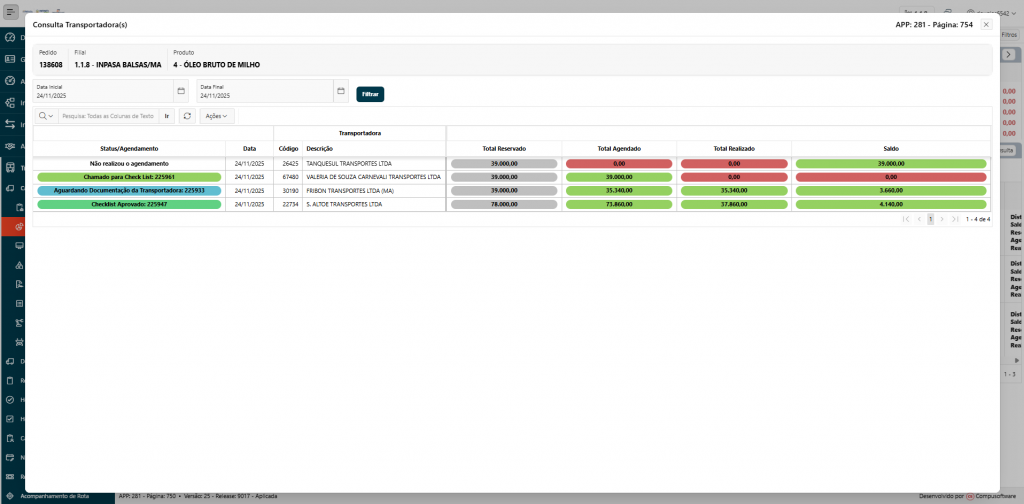

Inpasa’s new system, the Portal de Agendamentos, needed to handle more than 1,000 daily logistics transactions across its seven manufacturing units—with integrated management of thousands of vehicle movements and customer orders. The solution would also eliminate the need to maintain two or more separate systems for managing orders and schedules.

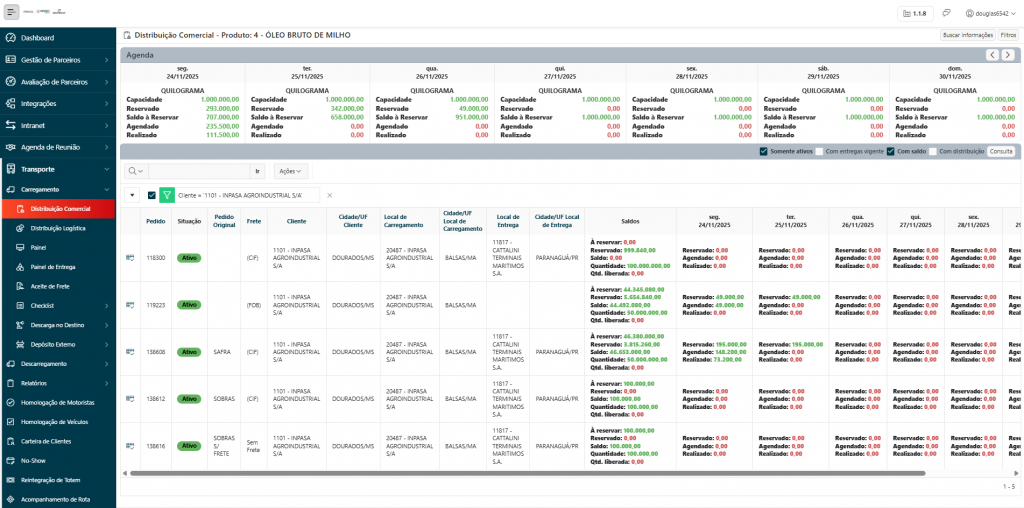

Another challenge to be overcome was aligning production capacity with order volume, ensuring integrated and efficient product loading and unloading operations—including ethanol, DDGS, premium oil, and even support for electricity generation. A detailed analysis conducted by the Inpasa technical team confirmed that Oracle APEX had the necessary functionalities to meet all these business demands.

Another decisive factor in choosing Oracle’s low-code platform was the short application development cycle, something the Inpasa has been able to confirm since adopting APEX. The new and robust portal could be built in just a few months with a small team of four developers.

“We transformed how we manage orders and logistics with the Portal de Agendamentos developed with Oracle APEX. In addition to reducing dependence on third-party logistics tools, the need to use other software applications dropped by 88%. We can now track an entire workflow in one place.”

— Douglas de Andrade de Souza, PMO, Inpasa

Results

Inpasa has been able to deploy Oracle APEX to replace its manual practices with a modern and scalable system that increased productivity, improved customer service, and fostered real-time collaboration across all business units, enabling faster and more confident decision-making.

Before implementing the modernization process, Inpasa’s teams had to manage orders and schedules through five or more separate systems. Today, the company uses the Portal de Agendamentos as a single solution that optimizes the end-to-end process — from commercial distribution to unit loading. The result was a reduction of up to 70% in the time taken to complete typical logistics tasks.

The portal also provides centralized visibility of delivery capacity. It is now possible to monitor and verify the capacity of all units on a single page in less than 20 minutes.

Oracle APEX has had a significant impact on Inpasa operations. The company now has complete control over its logistics, has minimized operational errors, and automated, data-driven decision-making has become a reality. Production capacity is now automatically aligned with orders and actual market demand. Customer service quality has also improved significantly, with a 60% reduction in manual requests and a reduction in response time from 2 hours to less than 30 minutes.

Inpasa has also developed a consolidated process for all areas of their operations (production, logistics, finance, and customer services). Clients and managers are able to track delivery progress, accounts payable status, vehicle locations, and even payment issuance in real time.

About the customer

Founded in 2006 in Paraguay, Inpasa is one of Latin America’s largest biorefineries. The company specializes in the production of biofuels, Distiller’s Dried Grains with Solubles (DDGS), and vegetable oils, with operations across Brazil and Paraguay.

Product list: Oracle APEX, Oracle Exadata