The manufacturing sector has arguably been the arena most impacted by industrial revolutions. Now, new terminology has emerged, such as smart manufacturing and the smart factory. To avoid confusion, it helps to recognize that smart manufacturing is the umbrella term, referring to the efforts to modernize industrial practices through smarter equipment, facilities, products, data, and processes. In smart factories, the production environment is run with minimal human intervention using new industrial manufacturing technologies, such as internet of things (IoT), robotics, and additive manufacturing.

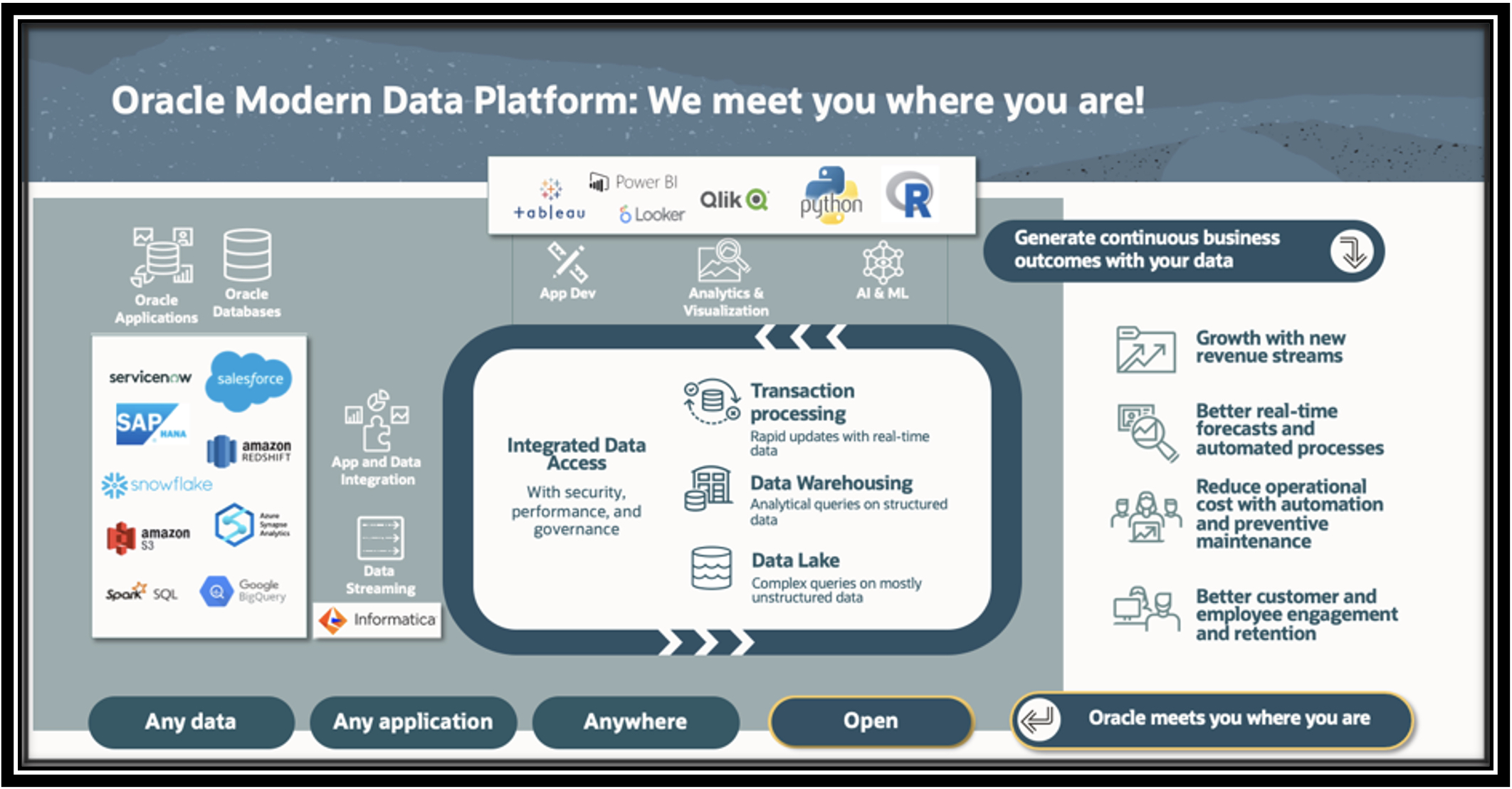

In today’s data-driven industrial landscape, efficiently managing and harnessing the power of time-series multi-sensor data is crucial for optimizing processes and staying competitive. Using cloud-based solutions like Oracle Modern Data Platform offers a robust and scalable approach to address these challenges. Oracle Cloud Infrastructure (OCI) offers cloud-based, hybrid, and multicloud solutions to customers.

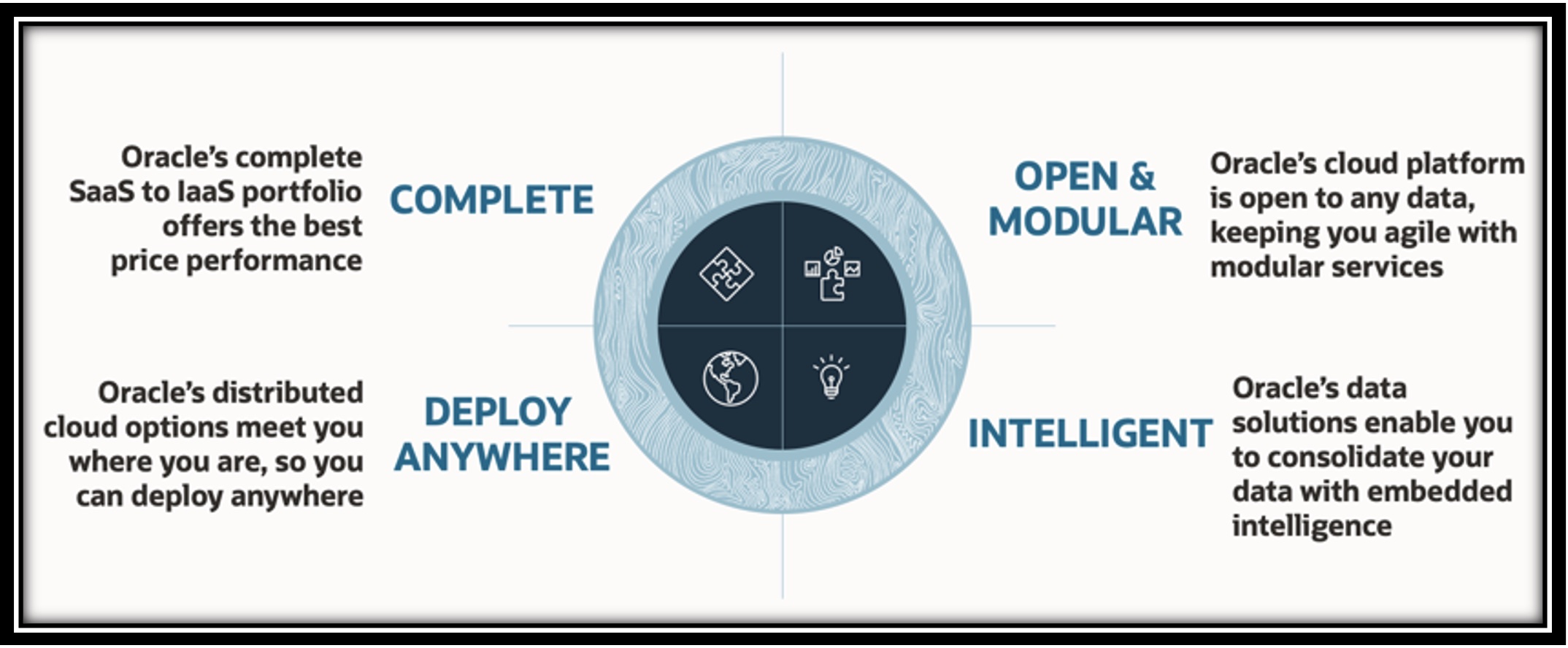

Embracing Oracle Modern Data Platform, organizations can not only overcome the challenges and complexities of data management but also gain the benefits from analytics, machine learning, and integration capabilities that are readily available on the cloud ecosystem. Oracle’s distributed cloud options meet you where you are, so you can deploy anywhere. It enables you to get real-time insights, do predictive maintenance and continuous feedback and improvement, ultimately leading to higher efficiency, reduced downtime, and lower total cost of ownership (TCO).

OCI Modern Data Platform

Let’s consider the case of a manufacturing company running its entire data and AI platform on a, on-premises data center. They want to modernize their production process, which involved collecting a large volume of time-series multisensor data from various machineries on the factory floors. This process includes data information on temperature, pressure, humidity, and other variables. The company needed a cost-effective but modern solution to improve production efficiency and reduce downtime.

The following challenges are associated with using an on-premises data center for managing time-Series multi-sensor data in an industrial manufacturing setting:

-

Cost and scalability

-

Physical security

-

Maintenance and redundancy

-

Data backup and recovery

-

Resource management

-

Data transfer and integration

-

Regulatory compliance

-

Adaptability to change

Despite these challenges some organizations opt for on-premises data centers because of data sovereignty requirements, security concerns, or industry specific regulations. However, they must carefully assess the trade-offs and consider hybrid cloud solutions that offer the flexibility to scale resources as needed, while maintaining control over critical data.

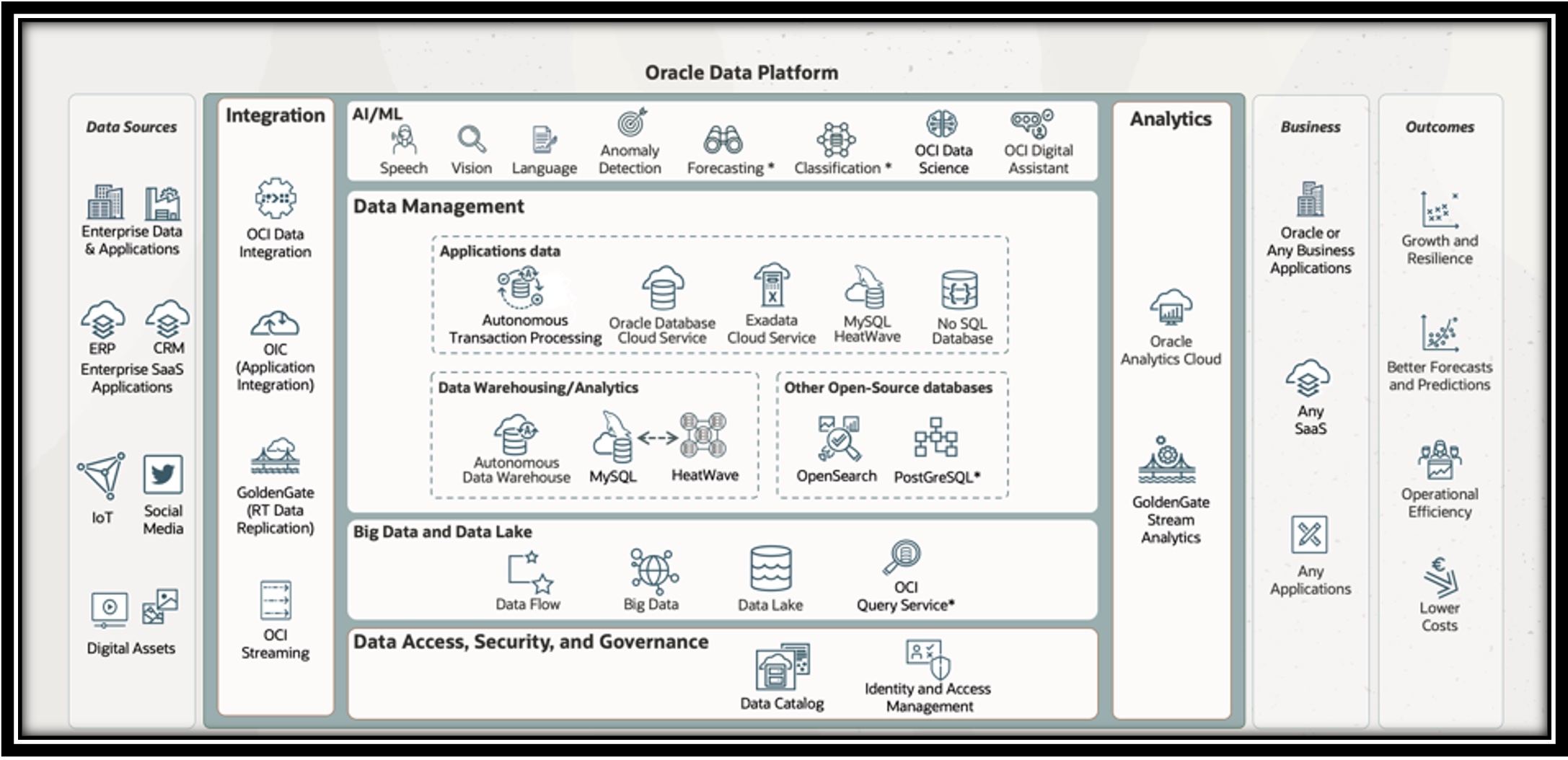

OCI can help you to work on developing a predictive maintenance system that utilized machine learning techniques to analyze the time-series multisensor data. The solution uses the following key features:

-

Data ingestion and storage: OCI data ingestion services, such as OCI Data Flow, OCI Data Integration, and OCI Golden Gate Streaming Analytics help you to efficiently ingest and preprocess the time-series multisensor data for batch and streaming. Users can seamlessly build extract transform load (ETL) pipelines and dashboards. Store the data in OCI’s highly scalable and secure Object Storage and Autonomous Data Warehouse, taking advantage of data tiering options for cost optimization. You can also use OCI Big Data Service for Apache Hadoop, Spark, Hive, Kafka, HBase, Trino, and more capabilities.

-

Continuous improvement: Implement a feedback loop using OCI Functions or Oracle Container Engine for Kubernetes (OKE) to continuously retrain and fine-tune machine learning models using new data. Collaborate with domain experts to refine feature engineering and modelling based on insights and feedback.

-

Analytics and visualization: Oracle Analytics Cloud (OAC) provides dashboards, reporting, alerting, self-service data preparation and end-user driven machine learning algorithms. You can also use third-party tools for this purpose.

-

Alerting and Integration: The OCI Notification service triggers real-time alerts when anomalies or impending failures are detected. Seamlessly integrate the predictive maintenance system with the company’s existing systems using OCI’s robust integration solutions.

-

Predictive maintenance: Develop machine learning models using AutoML capabilities or custom model training in OCI Data Science. Implement time-series forecasting techniques to estimate the remaining useful life (RUL) of machinery.

-

Anomaly Detection: OCI’s Anomaly Detection solution is an AI service that enables developers to more easily build business-specific anomaly detection models that flag critical incidents, resulting in faster time to detection and resolution. These models are trained on the central location and deployed as predictive model markup language (PMML) to run locally as Java or Python code. You can also deploy machine learning algorithms and libraries available in OCI, such as OCI Machine Learning, to detect anomalies and outliers in the sensor data. Set up alerts and notifications using OCI Events messaging when anomalies are detected.

-

Feature engineering: Leverage OCI Compute resources to extract relevant features from the time-series data, such as rolling statistics, trend analysis, and Fourier transformations. Implement OCI Data Science services for advanced feature engineering and model development.

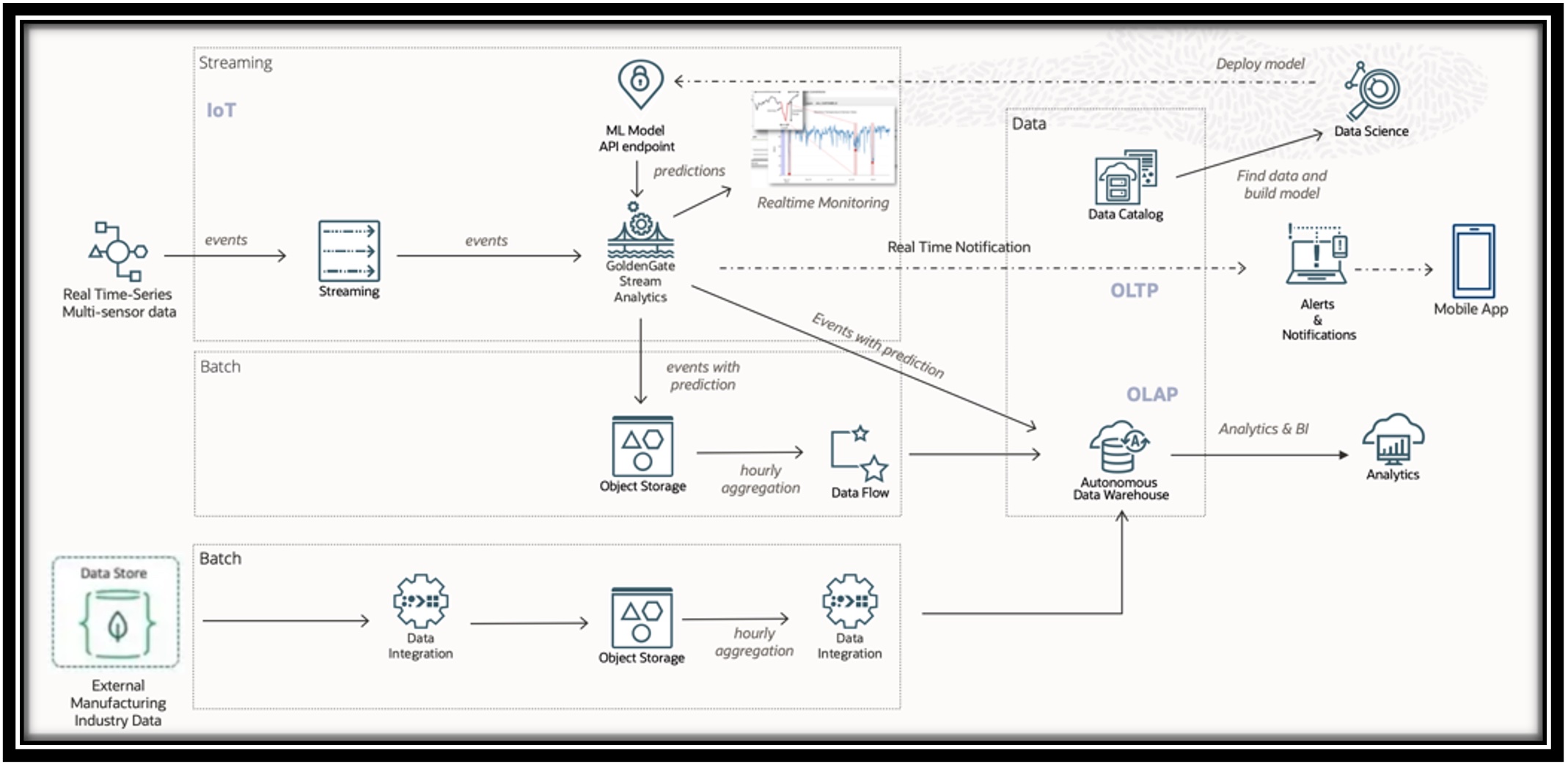

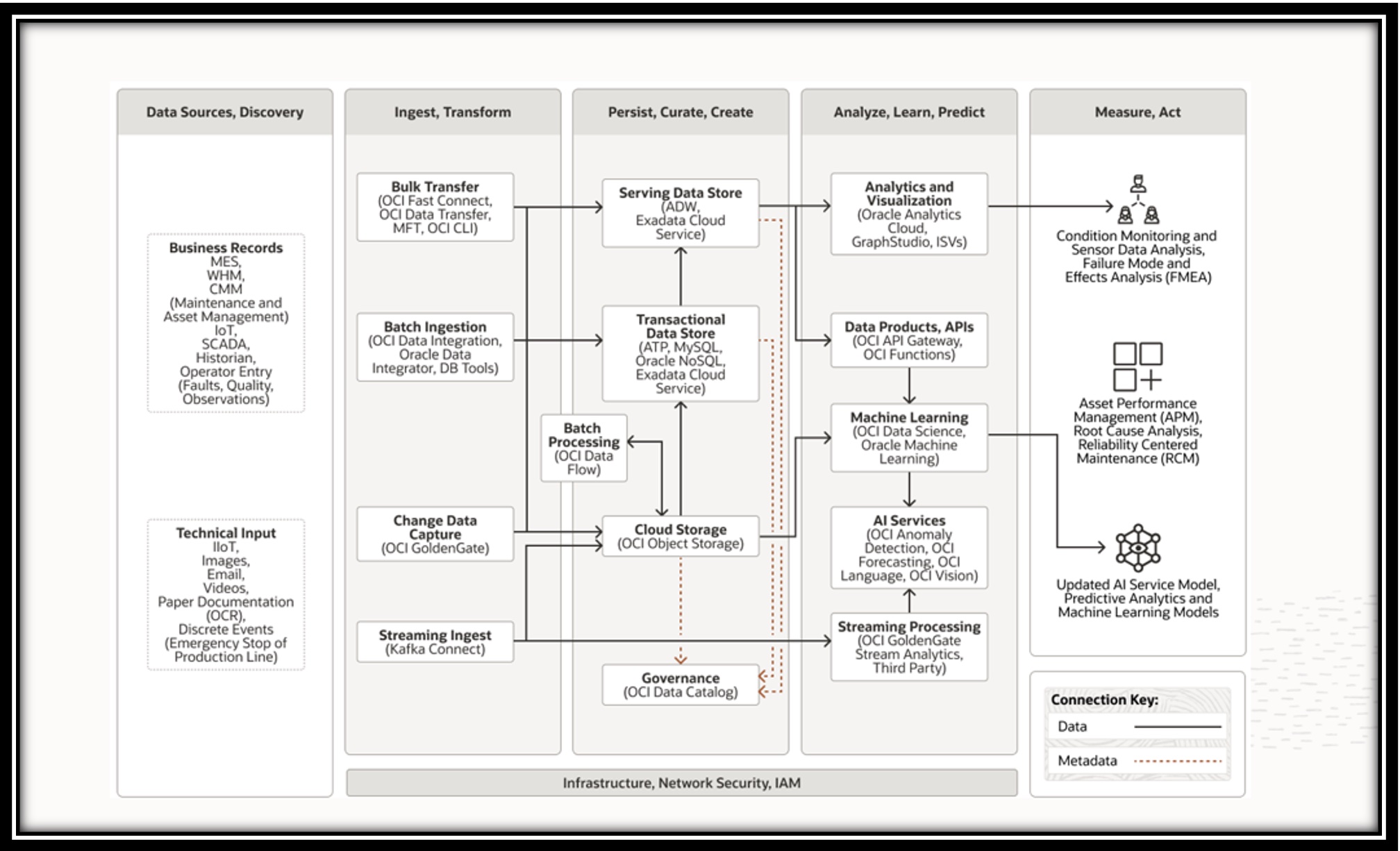

We implement the following typical architecture in such use cases, utilizing the richness of Oracle Data Platform portfolio of services.

Manufacturing Industry Architecture on OCI

Using Oracle Modern Data Platform, the company can significantly enhance production efficiency, reduce unplanned downtime, and optimize maintenance schedules. The cloud-based approach provides scalability, security, and flexibility, while effectively managing time series multi sensor data for industrial manufacturing applications. You can achieve the following high level flow on OCI Modern Data Platform.

See for yourself

As industries evolve and data volumes grows, migrating to Oracle Modern Data Platform can be a strategic solution to unlock the full potential of time-series multi sensor data, driving innovation and competitiveness in the industrial sector.

To get started today, sign up for the Oracle Cloud Free Trial or sign in to your account to try OCI Data Lake. You can also explore Industrial Manufacturing Cloud Infrastructure on Oracle Cloud Infrastructure.

Explore other labs in the Oracle Learning Center or access more free learning content on the Oracle Learning YouTube channel. Visit Oracle Learning Explorer to become an Oracle Learning Explorer. For product documentation, visit the Oracle Help Center.