This article was co-written with Sophie Petraman, Application Engineer at Noesis Solutions. Together, we will be presenting this case at NAFEMS France Conference 2022.

The automotive industry has been a pioneer in running numerical simulations. For a long time, this sector adopted design optimization strategies to reduce costs while maintaining high safety standards. However, certain types of simulations require more computational power, and reaching the convergence of an optimization algorithm can require hundreds of iterations. Here, Oracle Cloud Infrastructure (OCI) can help, where you can get hundreds or thousands of cores on demand for your projects and ensure that you can run your simulations. This blog describes how to automate an engineering simulation workflow and how easy it is to deploy clusters on demand on OCI.

Plastic injection and modal analysis on OCI

Let’s take the example of a plastic cover engine:

For this example, we’re running a modal analysis where we want to optimize the first mode. We also want to ensure that the parameters from the plastic injection simulation don’t exceed a certain value.

To answer this problem, we’re running the modal analysis using HyperMesh and Optistruct from Altair. The plastic injection is solved with Moldex3D, and the geometry is generated on FreeCAD. Here, we have a simulation workflow consisting of four types of software. All software runs on Oracle Linux 7.9 except the pre- and post-processing of Moldex3D, which uses Windows.

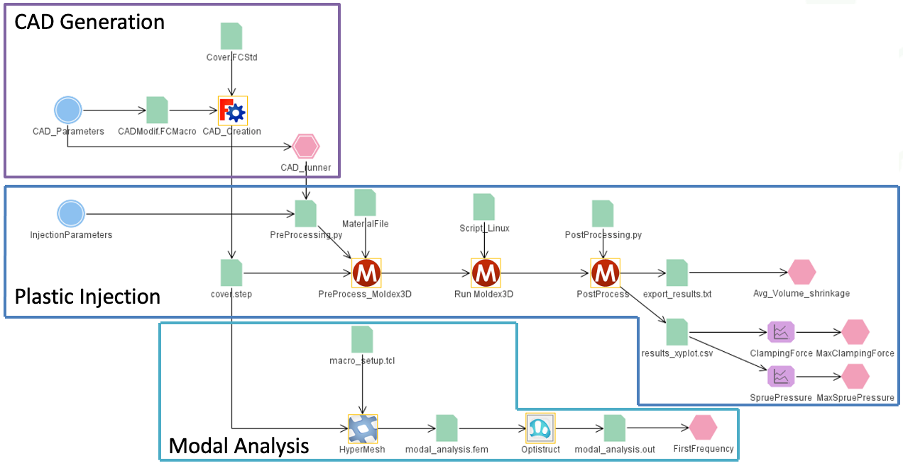

To automate this workflow, we take advantage of Optimus, a software developed by Noesis Solutions. Optimus is a software for process integration and design automation. It drives the different software required for our modal analysis and plastic injection analysis and gets the correct input and output files for the different stages. It also works on Windows and Linux, making the automation smooth. The following image shows the final automation workflow:

Automatic node deployment on OCI

Now that the automation is done, we can focus on the parallelization. Here, we want to run a genetic optimization algorithm from Optimus, which can require hundreds of simulations before converging. We can generate the geometry and run the modal analysis on one small machine, taking just a few second. The main issue resides in the solver of the plastic injection, which takes 3–4 hours on five cores.

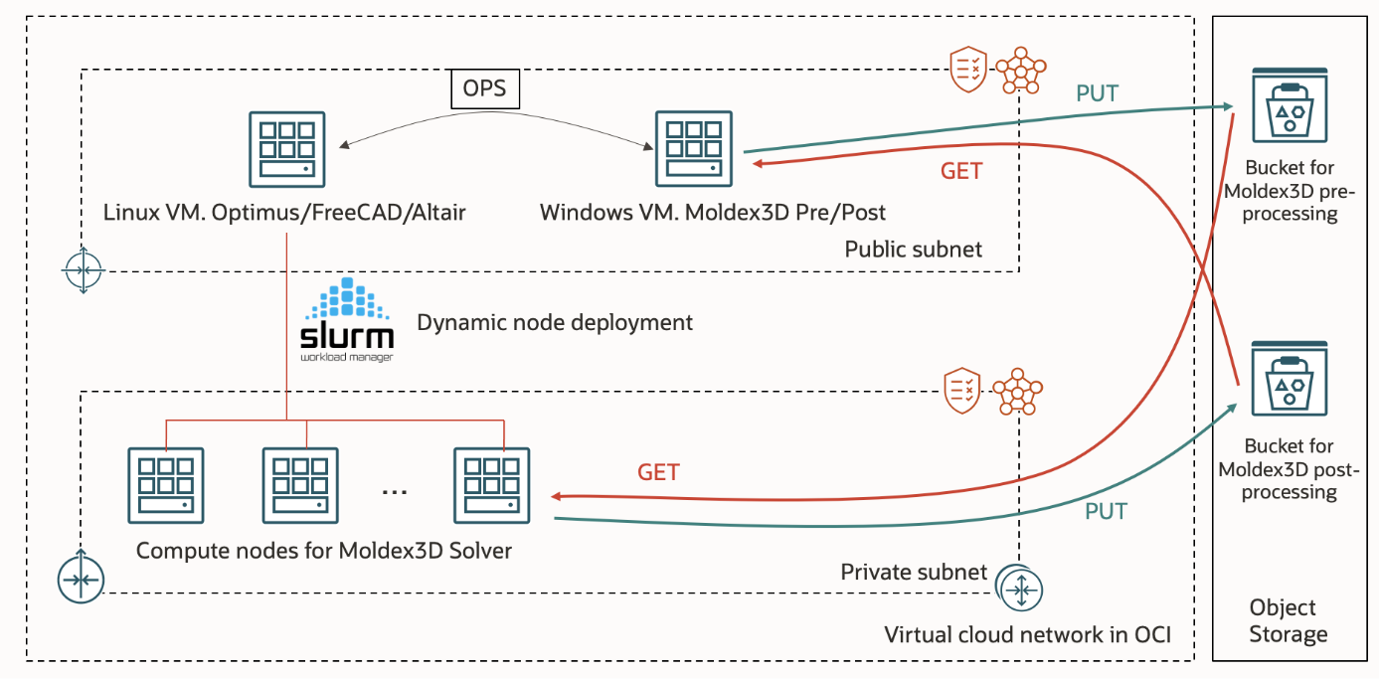

Here, OCI comes into play. For this test, we deploy machines to run the solver of Moldex3D so that it matches our licensing capability. We can have up to nine solvers running at the same time, and we don’t want to exceed six cores for each solver. So, we take advantage of the AMD Flex Shapes available on OCI and deploy up to nine VM.Standard.E4.Flex with six cores and 96 GB of RAM each. The automatic deployment, configuration and destruction are triggered by Slurm and directly available with our high-performance computing (HPC) stack available on the Oracle Cloud Marketplace.

The last step is the dataflow. We keep things simple and use the oci-cli and the OCI Object Storage service to move data in between stages. Optimus also has a tool to handle job submission and data exchange between Linux and Windows. The infrastructure looks like the following image:

This automatic deployment and the dataflow are completely transparent to the user. Everything is encapsulated within Optimus and driven behind the scenes.

Optimization results

The optimization proceeds, and after 20 hours, 110 experiments have run. The optimum gives an improvement of 33% compared to the baseline, and the algorithm stops.

These simulations can run over the weekend where an engineer starts the optimization on a Friday before leaving the office, and the results are in by Monday. Thanks to the dynamic deployment based on the state of the Slurm queue, no nodes are remaining idle, and the costs are optimized.

Conclusion

Running multidisciplinary optimization is now possible for anyone. The entire automation process is encapsulated in Optimus, and the infrastructure is automatically deployed.

Start your Oracle Cloud Infrastructure free trial today. For more information about Optimus, contact Noesis Solutions.