Manufacturing companies have been using analytics on data for various purposes: Demand forecasting, order management, equipment failures, product quality, and so on. Traditionally, companies have generated and stored tons of data in on-premises expensive data centers. In the past, manufactures have performed limited analytics manually using spreadsheets and operational dashboards, which are inefficient and costly. Oracle Cloud Infrastructure (OCI) solutions allow manufacturing companies to harness all the data that they generate to improve operational efficiency, streamline business processes, and uncover valuable insights that drive profits and growth. With the help of OCI, companies can now predict equipment failures in real time, improve quality of products, or increase production capacity with an improved supply chain.

Why cloud analytics makes sense for manufactures and how OCI can help

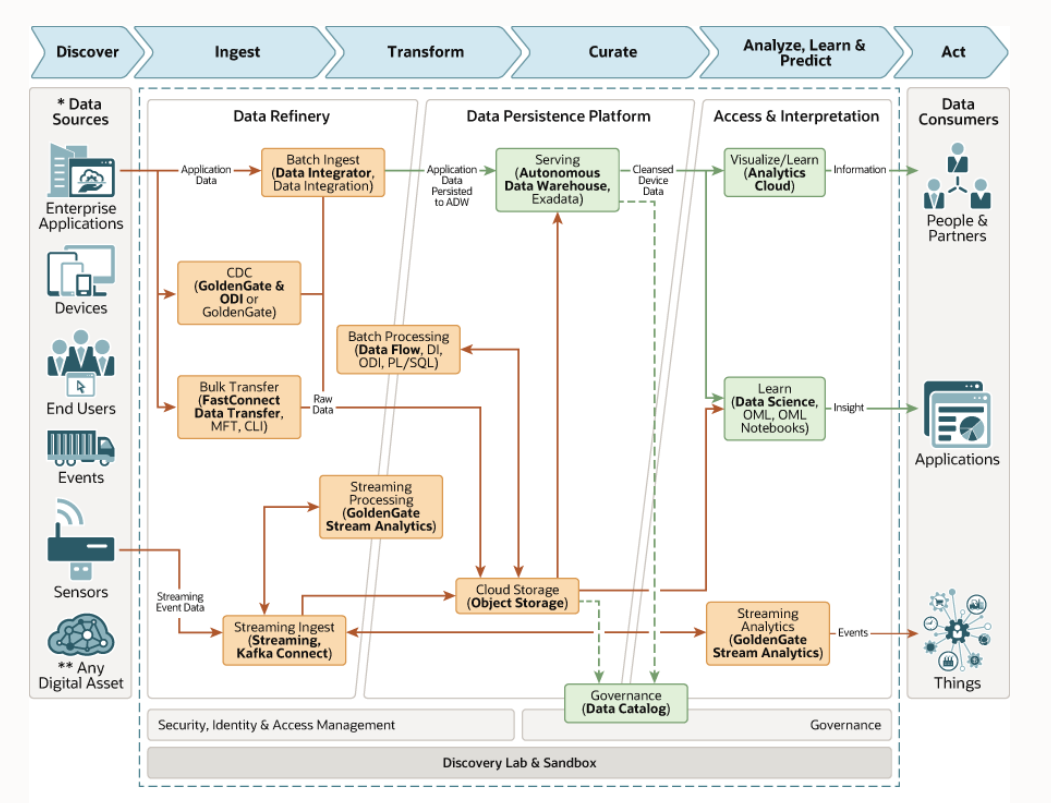

Figure 1. OCI Modern Data Platform

Cloud analytics has many benefits for the manufacturing industry.

As shown in Figure 1, manufacturing companies generate data through various data sources in different formats. To break these data silos for companies using traditional data warehouse solutions, OCI offers an industry-standard manufacturing data model, which is a comprehensive derived schema and STAR schema, consisting of 250+ industry measures and KPIs. You can easily convert data into a standardized data model, extend, and customize it.

Oracle Autonomous Data Warehouse has a standard manufacturing data model schema. OCI Data Integrator and GoldenGate services push the data utilizing this schema. Because companies can use the solution immediately, it provides faster solution to market. Developing such a data model from scratch normally takes companies more than five years.

Many subject matter experts (SMEs) can now access the data, which helps make better business decisions in real time across the organization. After the data is transformed into the manufacturing data model in Oracle Autonomous Data Warehouse, getting a 360-degree view of data is easier using Oracle Analytics Cloud (OAC) service, which gives deeper insights using prebuilt manufacturing dashboards.

Manufacturers can take advantage of various cutting-edge cloud services that cloud providers offer and don’t have to build them from scratch. OCI offers cutting edge Data Integration, Streaming, Oracle Analytics Cloud (OAC), machine learning, and cloud storage services that developers can take advantage to build modern data platform. As companies using traditional data warehouses realize the benefits of data lakes, they’re evolving their date warehouse to include data lakes. A data warehouse is a database optimized with data structure and schema, which are defined in advance, whereas a data lake is a single repository of structured and unstructured data stored as-is without having to structure the data, such as audio, video, images, and texts.

OCI’s modern data platform can combine the abilities of data lake and data warehouse to process streaming data and batch data, using real-time analytics and machine learning. OCI Object Storage is a scalable, high-performance storage platform that can store an unlimited amount of unstructured data with reliable and cost-efficient data durability. Developers can securely and easily store or retrieve data from Object Storage directly using REST API, command line interface (CLI), or OCI SDK.

Depending on the use case, data lakes can be built on Hadoop or Object Storage; Spark can be built on top for processing. Both can scale and seamlessly integrate with existing enterprise data and tools. OCI facilitates converged, open databases for multiple data types, including JSON, maps, and graphs, compared to the competition, who offer single purpose proprietary database for each datatype. OCI’s single-database approach is cost-effective compared to maintaining multiple databases.

Finally, manufacturers no longer need to maintain expensive data centers. OCI’s pay-as-you-go model is cost effective, secure, elastic, so companies don’t have to focus on the infrastructure and can focus more on solving complex problems.

Manufacturing analytics on OCI

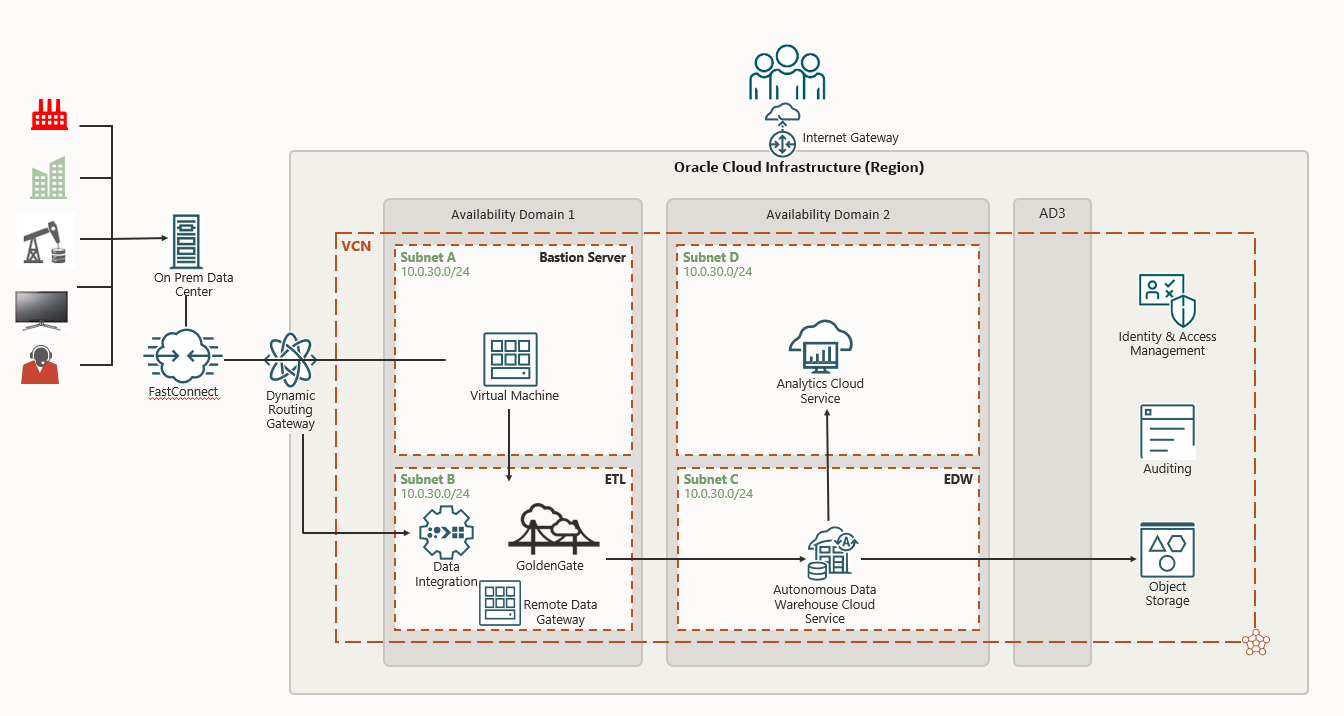

Figure 2. OCI Manufacturing analytics reference architecture

For a traditional data warehouse use case, the recommended reference architecture has the following components:

- Data from various manufacturing sources is stored in an on-premises data center and then brought into an OCI virtual cloud network (VCN) using FastConnect and a dedicated, private, high-bandwidth connection.

- OCI Data Integration and OCI GoldenGate services unify all these data silos using extract, transform, load (ETL). ETL operates by first extracting the data from various sources, transforming it in a proprietary, middle-tier ETL engine used as the staging area, and then loading the transformed data into the target data warehouse. Data Integration works on the batch data and GoldenGate is for real-time data.

- The transformed data is stored in Oracle Autonomous Data Warehouse, which has a standard manufacturing data model schema. Data Integration and GoldenGate push the data into this schema.

- SMEs can then use Oracle Analytics Cloud (OAC) to gain powerful insights driven by Oracle Machine Learning (OML).

Ready to get started?

Let us help you solve your analytics problems for running your manufacturing workloads. Try Oracle Cloud Infrastructure for free. Get more information on Oracle Cloud Free Tier or 30-day free trial, which includes US $300 in credit to get you started with a range of services, including compute, storage, and networking.